二手 TEL / TOKYO ELECTRON Alpha 303i-K #9373155 待售

網址複製成功!

單擊可縮放

ID: 9373155

晶圓大小: 12"

優質的: 2006

Vertical LPCVD furnace, 12"

Process: TEOS

(100) Process wafers

I/O Port / SMIF: FOUP

No load lock

25-Carrier slots

Boat type: Single

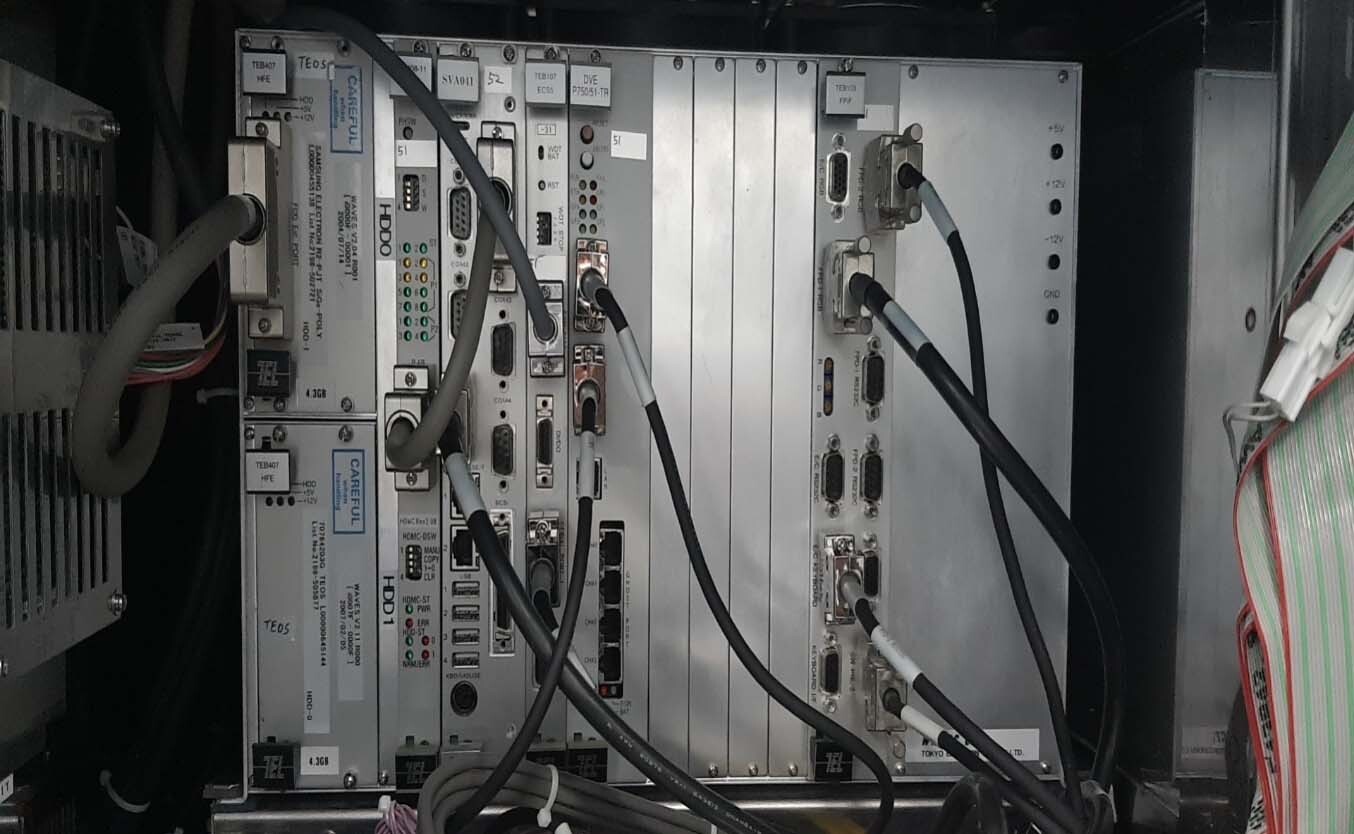

Main controller (WAVES)

Operation screen: Touch screen

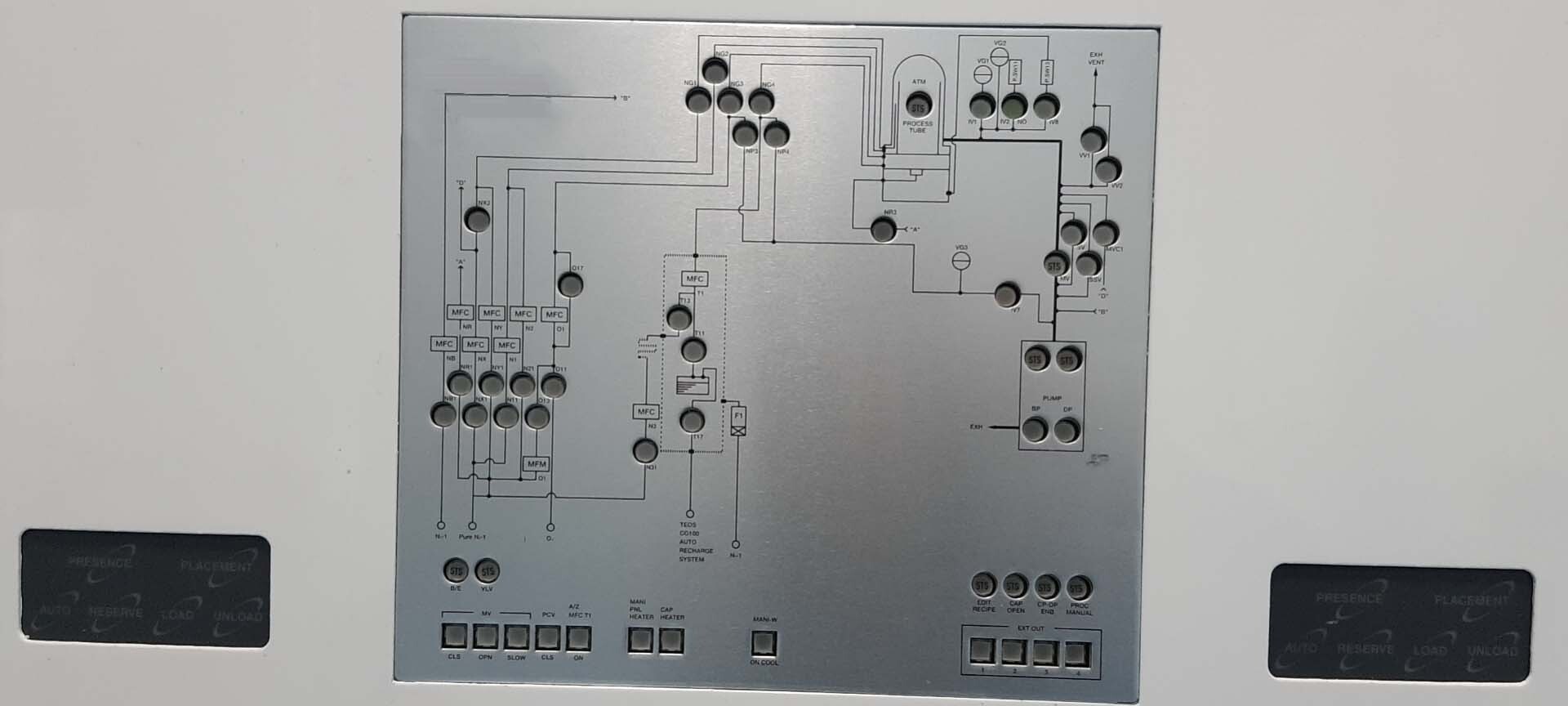

Gas flow chart: Front and rear

M560 Temperature controller

Vacuum pressure control: CKD VEC

Controller transformer: 208 V, Single phase

Heater transformer: 208 V, 3 Phase

Gases:

Gas 1: N2

Gas 2: N2

Gas 3: O2

Gas 4: TEOS

Gas 5: N2

Gas distribution:

Basic style: Conventional

Tubing material: SUS-316L

Tubing finish: VCR

Manual valve: CKD

Air operated valve: CKD

MFC: HORIBA STEC

Exhaust distribution:

Air operated valve type: IGS Connect

Main valve: CKD VEC

Cold trap

No pump line

Wafer / Cassette handling:

(16) Cassette storage

Cassette In/Out port

Cassette handling robot

Wafer transfer type: 1 + 4

Fork material: AL2O3

Fork variable pitch

Fork wafer presence sensor

Elevator handling:

Boat elevator

Auto shutter

Boat rotation

Mechanical parts

Heating chamber:

Heater type: VMM-56-002, 100 wfs

(5) T/C Type

(5) Spike T/C

Furnace cabinets includes clean air flow system

Scavenger and water cooling unit

Power supply unit (U/P Box):

Control unit

Transformers

SCR

Breaker unit

FOUP and wafer handling automation:

(2) FOUP Load ports

FOUP Transfer

Stocker: (18) FOUPs

FIMS Port

KHI Wafer load automation

Variable pitch change mechanism with (5) forks

Auto tube shutter

Boat elevator with boat rotation mechanism

Integrated gas system in gas cabinet and TEOS LSC baking system:

O2 Gas line

TEOS Gas line

Purge N2

Vacuum vent

Exhaust vent

Piping tape heater

Main valve type: CKD Hot, P/N: VEC-VH8G-X0101

Vacuum gage

Pressure switch

Piping: 100 A VAC

Does not include:

Outer/Inner T/C

N2 Load lock

N2 Boat cooling shower

Dual boat operation

B.S Sensor: 0-10 Torr, 0-1000 Torr

Cable length: 12 m (Power box)

AC Power box: 208V,3 Phase, 4 Wires

2006 vintage.

TEL/TOKYO ELECTRON ALPHA 303i-K是一種先進的擴散爐及配件設備,使客戶能夠進行高質量、低成本、高通量的半導體制造加工。該系統具有單區爐、氣體輸送裝置、板載晶片裝載機、自動晶片傳輸臂和控制器。單區爐利用低速、低膨脹石英管滿足部件擴散要求,提高了熱均勻性和晶圓溫度穩定性。TEL ALPHA 303IK的最高工作溫度為1,100 °C (2,012 °F),非常適合介電層和金屬化層及相關工藝。此外,該機器還采用了一種創新的保護性大氣氣體停滯工具,這種工具有助於確保一致的流量和響應,從而在各種氣體的情況下實現最佳性能。板載晶片加載器提供了一種將晶片快速可靠地送入資產的高效、自動化的方法。TOKYO ELECTRON ALPHA 303 I K憑借其大容量和多重負載選項,裝備精良,可處理多種晶圓尺寸和基板。結合自動晶片傳輸臂,ALPHA 303IK無需手動處理晶片,從而提高了吞吐量時間。該型號易於操作和維護,其控制器具有直觀設計的菜單和窗口,可增強可用性。控制器提供坡道和浸泡設置、爐子操作參數和氣體輸送設置等控制參數。此外,控制器還可以與外部PC連接,以便遠程監控和評估流程數據,從而確保流程性能和可靠性。TOKYO ELECTRON ALPHA 303i-K是客戶需要高效、經濟高效的擴散爐及配件設備的終極解決方案。該系統具有單區爐、自動晶片傳輸臂、車載晶片裝載機、保護性大氣氣體停滯裝置和直觀控制器。TEL ALPHA 303 I K完全自動化,用戶友好,性能可靠,是要求苛刻的半導體制造工藝的理想選擇。

還沒有評論