二手 KLA / TENCOR 2132 #139716 待售

網址複製成功!

單擊可縮放

ID: 139716

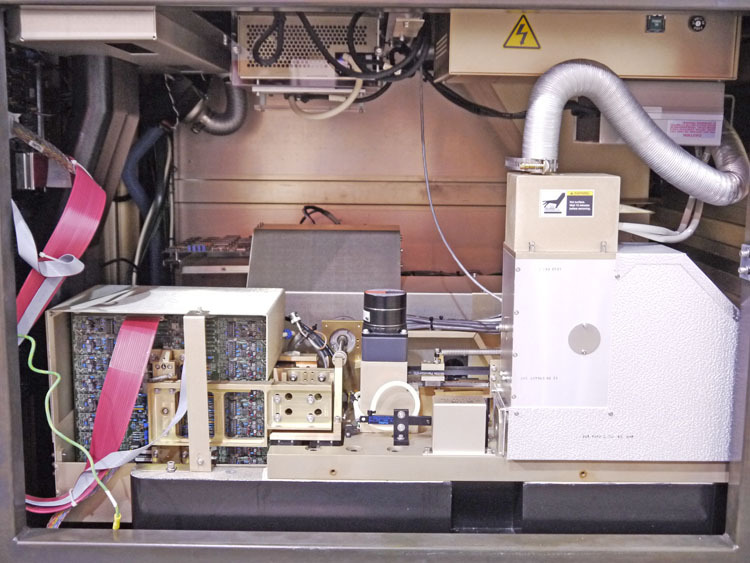

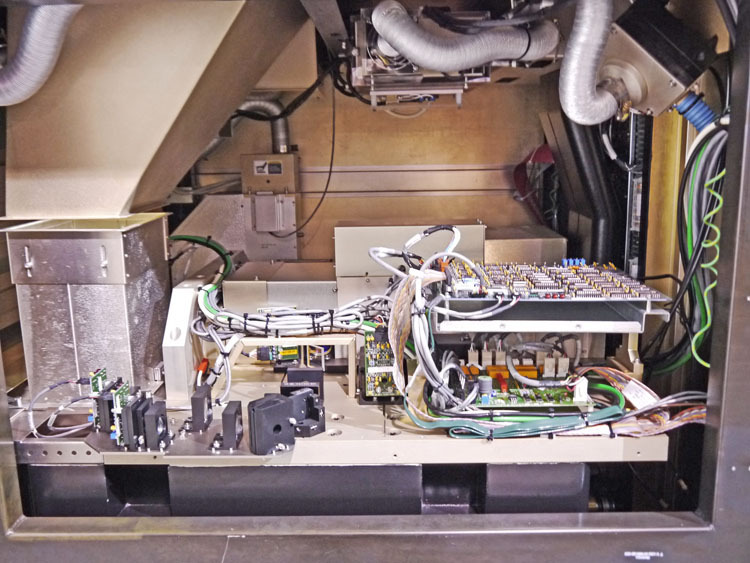

Wafer defect inspection system

Includes:

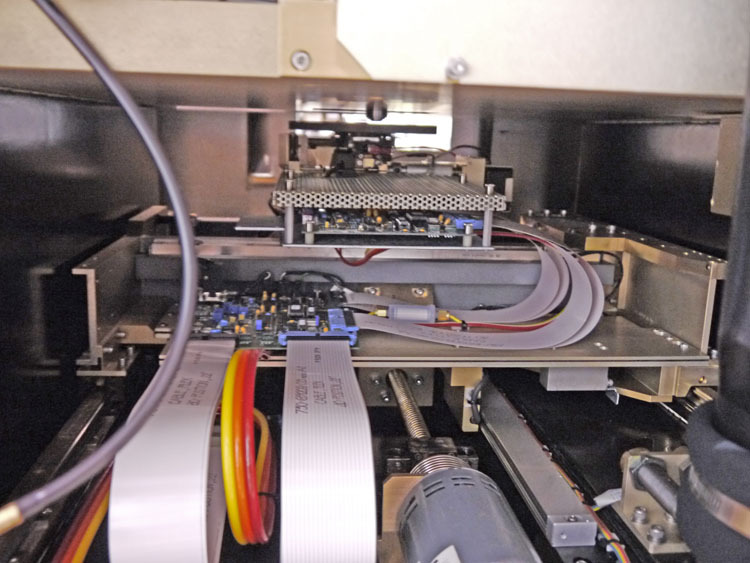

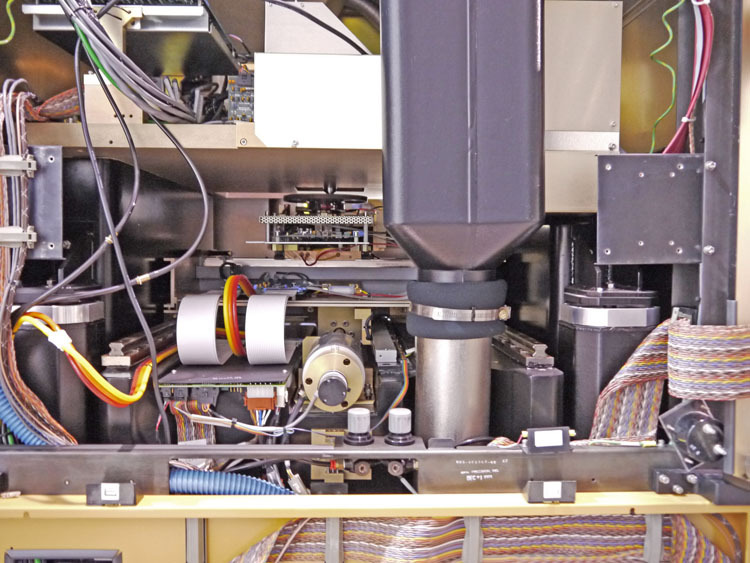

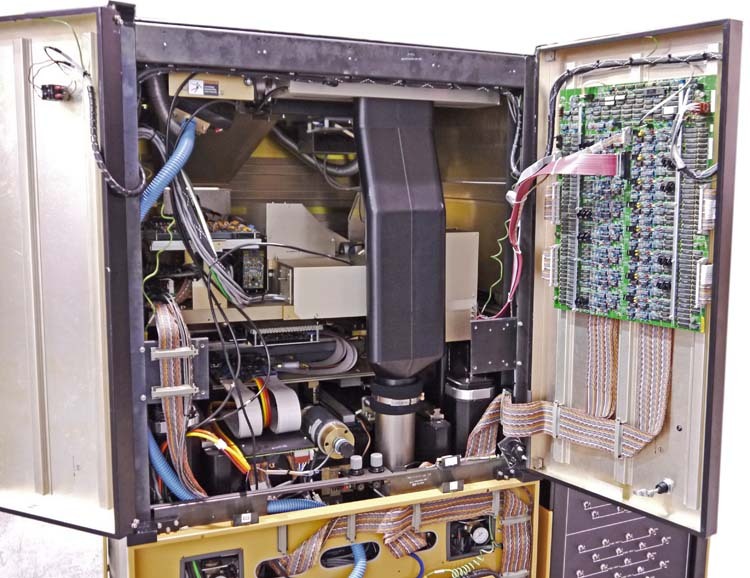

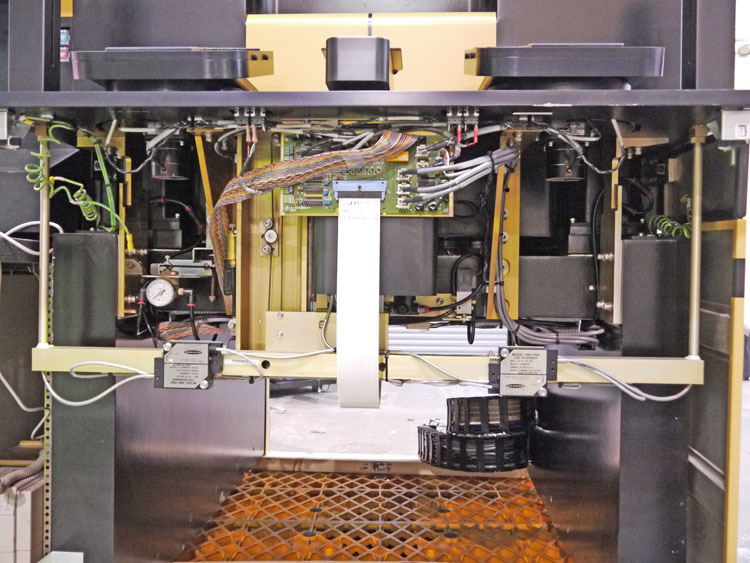

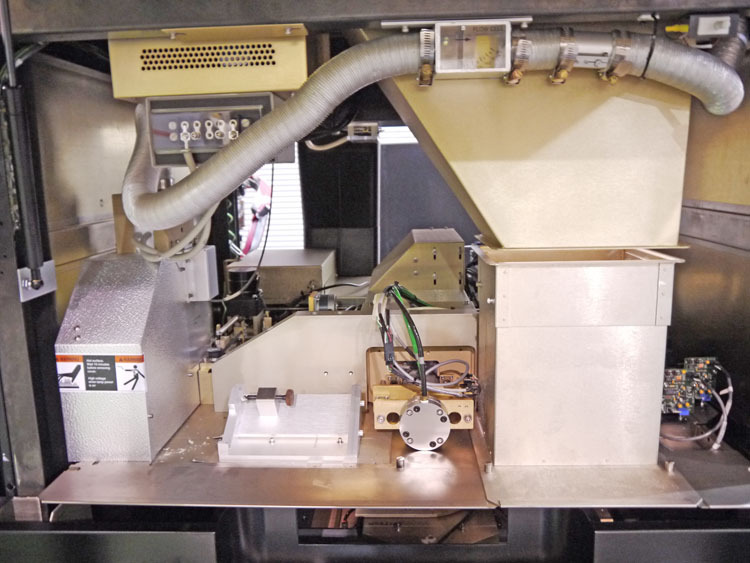

KLA / TENCOR 2132 wafer inspection unit (primary)

KLA / TENCOR 2132 wafer inspection unit (secondary)

KLA / TENCOR 2552 data analysis station

KLA / TENCOR 2132 power line conditioner

Specifications:

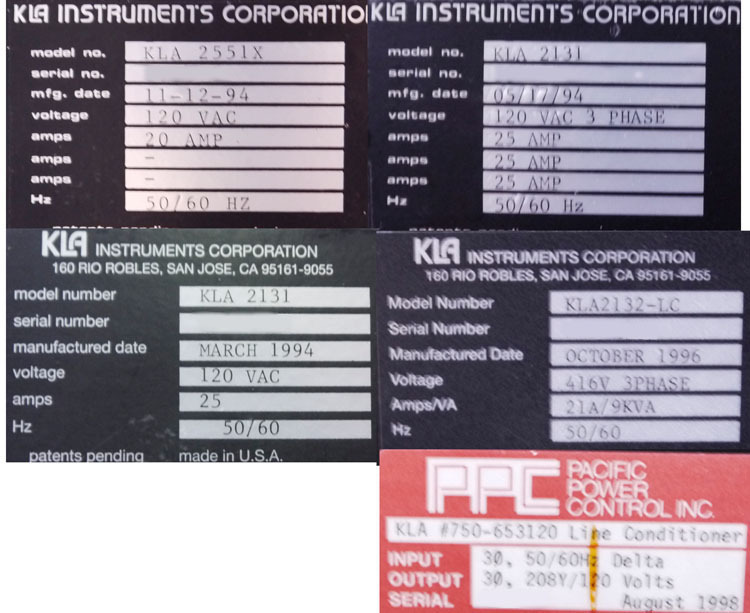

KLA / TENCOR 2132 wafer inspection unit (primary):

Label model: KLA-2131, front panel reads "2132"

Chuck installed: 8"

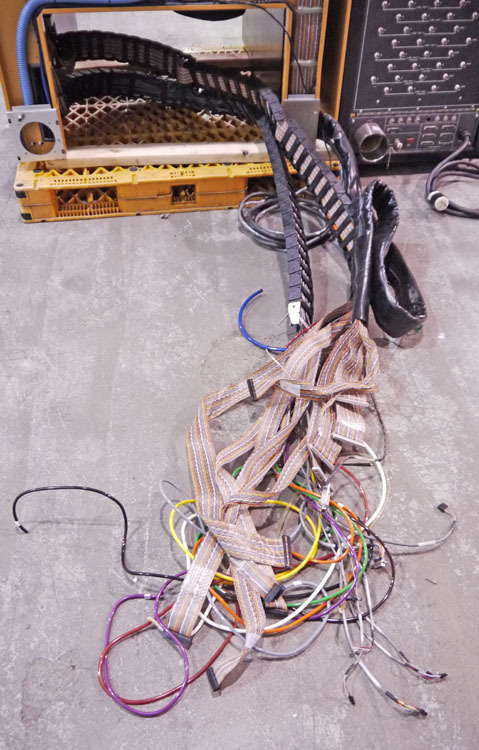

Power cable intact, all other cables cut

Front upper panel cover shocks / struts are worn

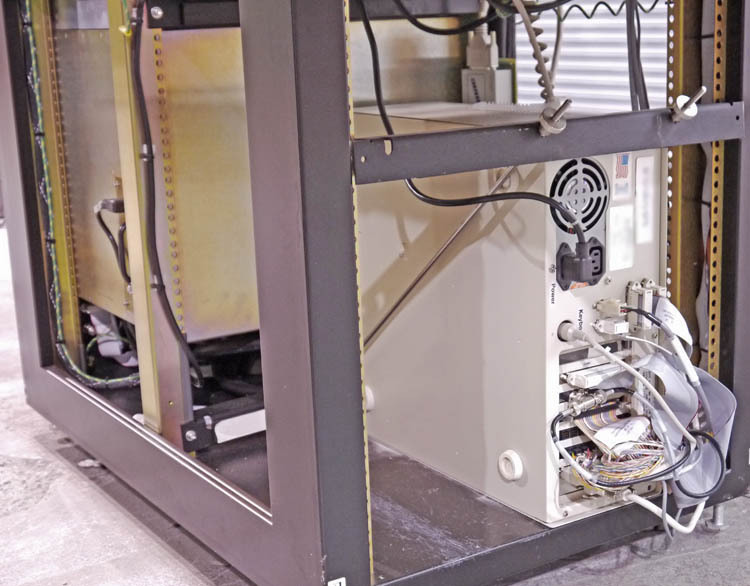

Missing: PC, 1-2 body panels

Power rating: 120VAC, 25A, 50/60Hz

1994 vintage

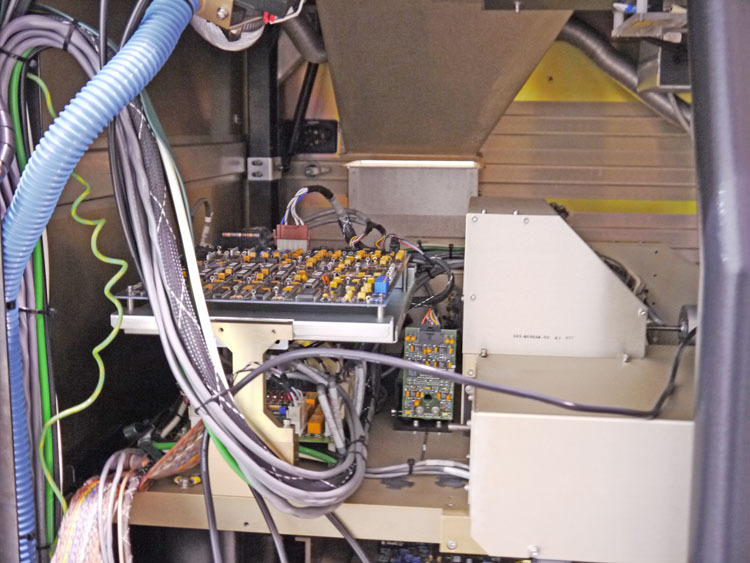

KLA / TENCOR 2132 wafer inspection unit (secondary):

Label model: KLA-2131, front panel reads "2132"

Body panel does not fully mount

Power rating: 120VAC, 3-phase, 25A, 50/60Hz

1994 vintage

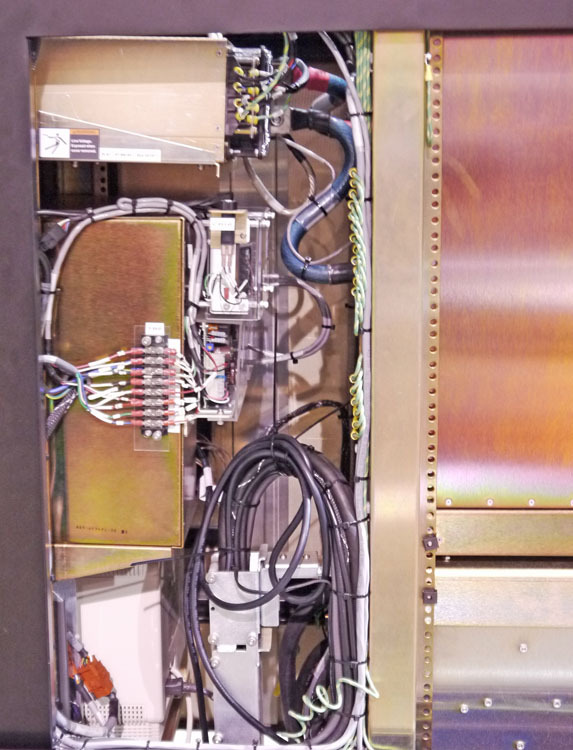

Components:

KLA PC/IF 486/66 PC system, p/n 750-660859-00

Dual monitors

Keyboard

Trackball

Modules installed:

KLA PC/IF 486/66 PC system, p/n 750-660859-00

KLA Memory Controller Phase 3, p/n 710-658232-20

FAB, p/n 710-658085-00

(2) Mass Memory 2 Phase, p/n 710-658051-20

(2) KLA CornerTurn 3, p/n 710-655651-20

(2) Y-Interpolator, p/n 710-658172-20

(2) X-Interpolator, p/n 710-658177-20

UNIQUENESS Processor, p/n 073-658045-00

Alignment Processor Phase 3, p/n 710-658041-20

Alignment Processor (AP1), p/n 710-65803620

Defect Filter (H.R.), p/n 710-659724-00

Defect Processor Phase 3, p/n 710-658075-20

KLA DP, p/n 710-650099-20

KLA DD, p/n 710-650044-20

KLA DF FAB PH3073, p/n 073-65836-00

IB Module

RIF Module

KLA / TENCOR 2552 data analysis station:

Label model: KLA-2551X, front panel reads "2552"

Power rating: 120VAC, 20A, 50/60Hz

1994 vintage

Components:

INTEL XBASE8TE8F-C PC computer tower

APC BackUPS

Dual monitors

Keyboard

Trackball

KLA / TENCOR 2132-LC power line conditioner:

P/N: 750-653120

Power rating: 9kVA, 416V, 21A, 3-phase, 50/60Hz

Input: 3-phase, 50/60Hz

Output: 3-phase, 208V/120V

1996 vintage

System currently de-installed.

KLA/TENCOR 2132是一款功能齊全、自動化的面罩和晶圓檢測設備。它具有先進、高性能的傳感器和先進的成像技術,可用於高精度、精確的檢查。該系統采用明線、明亮缺陷、暗區缺陷成像傳感器,改進缺陷分類,高速自動缺陷審查和缺陷處理。該設備可提供無與倫比的缺陷識別和精確的缺陷處理,每小時最多可處理60個晶圓。它是一種非接觸式、無破壞性的機器,在整個檢測過程中確保晶片對基板的完整性。憑借其先進的傳感器技術,該工具能夠分析各種基板,包括矽、光刻膠、玻璃和陶瓷,尺寸可達300毫米。資產的先進成像技術包括各種成像模式,從而能夠檢查任何等級的半導體晶圓。晶片表面的高分辨率圖像通過各種透鏡和光學預設來捕獲,從而能夠快速、輕松地全面概述晶片。有三種類型的成像模式可用於特定於任務的檢查:高放大倍率圖像、平面圖像、3D圖像。該模型還提供了改進的缺陷分類和分類功能。通過將明亮的線條、明亮的缺陷和深色缺陷圖像與不同角度的光相結合,該設備能夠高精度地表征缺陷。缺陷會自動實時分類,並根據其性質的嚴重性分類成組。使用高級3D缺陷分析模塊,可以創建晶圓表面缺陷的詳細3D映射。KLA 2132是一個非常寶貴的工具,用於檢測和處理缺陷,提高精度和準確性。它具有強大的特性,有助於提高產量和減少晶片廢料,以滿足各種晶片檢驗需求。

還沒有評論