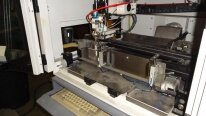

二手 ASYMTEK C 740 #9160279 待售

網址複製成功!

單擊可縮放

ID: 9160279

優質的: 2004

Conformal coating machine

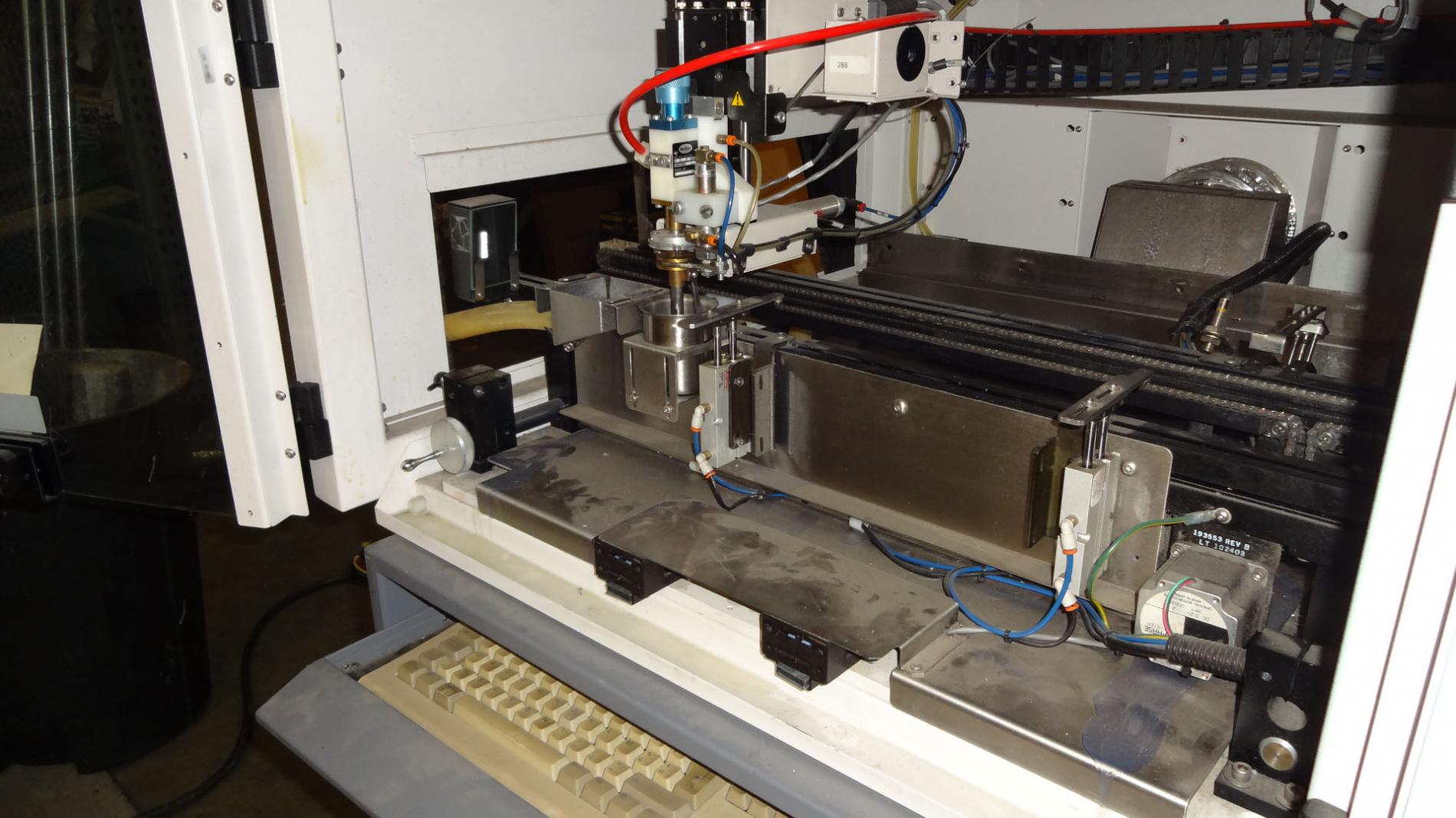

Single head

User environment: Easy coat fluid move

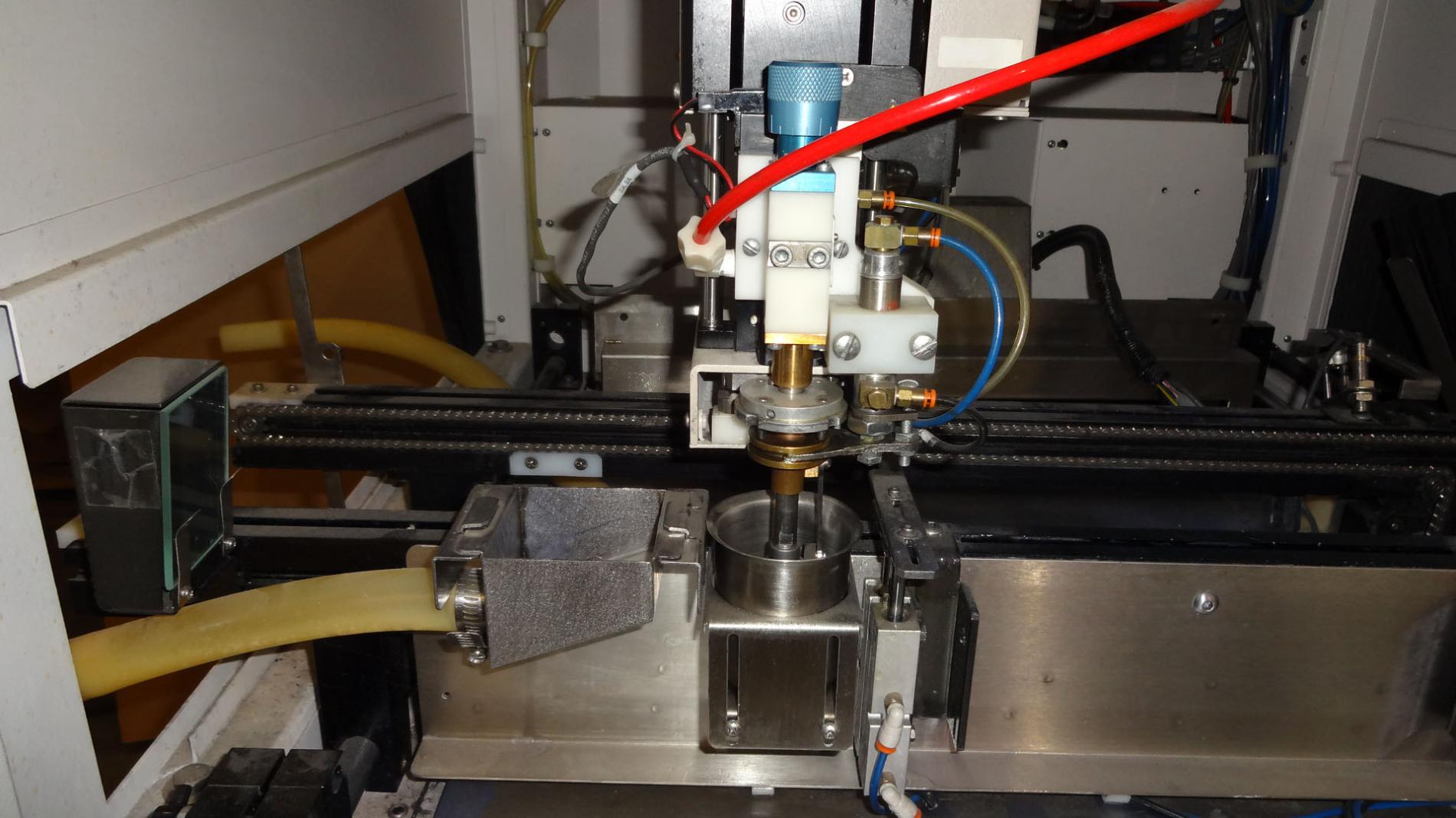

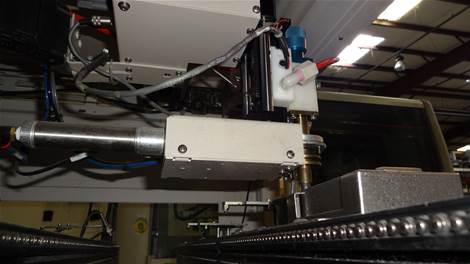

SC-200 valve

Operating system: Windows NT

Laser fan width control

Dispense area: 457 x 432 mm

Purge and solvent cups:

Door interlocks

Light beacon

Conveyor:

Chain conveyor with queue stop and pinning set

Manual width adjust 2-18 inches

System foot print: 36 x 41 inches

Power: 100 / 120 / 220 / 240

50/60 Hz, 10 amps

Motion system:

Type: Brush-less DC stepper motor

X-Y velocity:

Maximum: 508 mm/s (20 in./s)

Default: 381 mm/s (15 in./s)

Z axis velocity: 203 mm/s (8 in./s)

X-Y repeatability: ±0.025 mm (0.001 in.), 3 sigma

Z-axis repeatability: ±0.025 mm (0.001 in.), 3 sigma

X-Y resolution: ±0.025 mm (0.001 in.), 3 sigma

Z-Axis resolution: ±0.025 mm (0.001 in.), 3 sigma

Positional accuracy: ±0.13 mm (0.005 in.), 3 sigma

Dispense area:

Inline: 457 x 432 mm (18 x 17")

With solvent-purge station: 457 x 400 mm (18 x 15.75")

With fan width control: 457 x 387 mm (18 x 15.25")

Board size up to 400 mm (15.5") wide can be accommodated

Conveyor:

Inline: Standard chain conveyor with queue stop and pinning set

Manual width adjustment from 51 to 457 mm (2 to 18")

Maximum clearance: 89 mm (3.5") above and below PCB

Maximum pallet / PCB weight: 2 kg (5.5 lbs)

Computer:

Computer: Pentium PC

User interface: Monitor, keyboard and mouse

User environment: Easy coat for Windows NT

Operating system: Windows NT

Fluid delivery method: SC-104/105

Film coater module: Non-atomizing, heat-circulating system SC-204/205

Film coater module: Non-atomizing, non-circulating system

Swirl coat module: Tri-mode swirl system

Facilities requirements:

Air supply: 620 kPa (90 psi, 6.2 Bar), up to 57 liter/min (2 SCFM) max depending on configuration

Ventilation air: 0.28 m3/s @ 25 mm water column (600 SCFM @ 1.0" water column)

Nitrogen source: Required for moisture-sensitive materials – 410 kPa (60 psi, 4.1 Bar) @ 14 liter/min. (0.5 CFM)

Power (Mains): 100/120/220/240 VAC 50/60 Hz, 10 A

Noise: <70 dBA

Standard compliance: SMEMA, CE

Configured with valve, SC204 film coater

Inline machine

2004 vintage.

ASYMTEK C 740是一種高性能的自動註射器分配設備,設計用於提供精確和可重復的光刻膠分配。該系統提供業界領先的配藥精度± 1%(按容積),確保組件或電路板的零件尺寸準確。用戶界面被開發為允許快速、輕松和直觀的操作,允許用戶最大限度地提高吞吐量和周期時間。C 740獨特的模塊化設計使用戶能夠獲得更大程度的靈活性和對分配過程的控制。該設備是可擴展的,最多有五個分配軸,可配置用於各種應用程序。該機還針對低流體壓力和使用量進行了優化,減少了殘留和汙染。ASYMTEK C 740配備了多角度視覺工具,確保零件的準確放置和可靠分配到各種目標表面,包括金屬、塑料、玻璃和泡沫。視覺資產還支持面膜的自動生成,允許光刻膠圖案被精確和重復地放置。該模型結合了先進的高速軟件,可集成到生產線中,實現真正的自動化過程。可以遠程訪問設備的許多組件,從而提高了操作效率。C 740專為與多種材料兼容而設計,包括光刻膠、環氧樹脂、焊膏和粘合劑-使用戶能夠優化工藝參數並提高吞吐量。該系統還設計用於清潔室和室外環境,允許用戶在多個位置擴展靈活性。ASYMTEK C 740可為各種光刻膠應用提供可靠的生產質量。簡單的設置和操作,加上業界領先的配藥精度,使該設備能夠在各種應用程序中提供緊密的生產容忍度。

還沒有評論