二手 DMC SA/4m #143323 待售

網址複製成功!

單擊可縮放

ID: 143323

晶圓大小: 8"

優質的: 2006

Wafer-level Electro Plating system, 8"

Used for Stamper and micro pattern electro-plating

Can be implement as high uniformity

Using cathode head rotating system can produce high-quality products

This equipment can be applied to MEMS type and performed on the trench fill electroplating

Process automation can be set with Independent program for each cell

Various plating condition can be set with Independent program for each cell

DC, pulse, pulse- reverse current can be supplied in the resolution ±1 mA

Ni, Ni-CO, Cu Electroplating can be performed with this equipment

Total solution volume: 500 liters

Features:

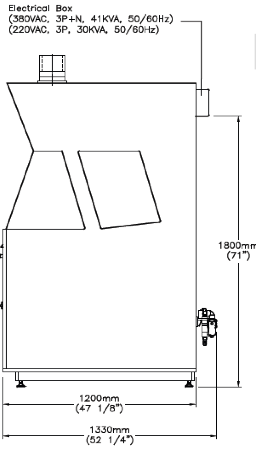

Small Footprint

Independent Pump/Filtration for each cell

Patented adjustable cathode head and workholder for precise control of thickness variation

Front access for maintenance

Integrated all-in-one design, integrated sump & electronics

Enclosed work area for process control

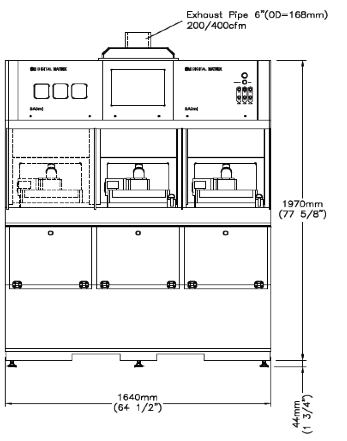

Industrial PC control with large flat panel touch-screen display

Switch mode rectifiers

Easy operator interface

All digital Control system

(Qty 3) Cells:

Pump: 1 HP

Heater: 6 kW

Rectifier: Standard 65 Amps, 24VDC

Filtration: 2 Stage

Pre-filter: 5 micron DOE, 20"

Final-filter: 0.45 micron DOE, 20"

Flow: 50 liter max (Adjustable)

2006 vintage.

DMC SA/4m是杜邦MicroCircuit Materials製造的光刻膠設備。該系統在有機基座上使用感光聚合物層,常用於生產電路板和其他電子應用中發現的銅和鋁基板。DMC SA/4m光致抗蝕劑單元由覆蓋在柔性聚酯基板上的有機膜組成。該基層為頂部的光敏聚合物層提供剛度和保護。聚合物層包括樹脂,如聚酰亞胺、聚甲基丙烯酸酯、聚丙烯酸酯、聚碳酸酯和聚苯乙烯,所有這些都可以塗覆在各種厚度的基層上,以適應不同的底物構型。光致抗蝕劑被光激活,引起光化學反應,其中某些區域暴露,而其他區域受到保護。受保護區域保持其原始形式,而暴露區域則發生化學變化,根據聚合物層的組成而變得可溶性或不溶性。可溶性聚合物在沖洗過程中被蝕刻掉,然後剩下的不溶性區域被化學磨掉。此過程將刪除不需要的材料,並為產品創建所需的形狀。DMC SA/4m光致抗蝕劑機通常應用於濕式層壓工藝中,采用均勻的薄膜厚度,然後進行徹底幹燥和化學預處理。一旦塗上了薄膜,就可以在化學蝕刻之前用光源曝光並顯影。開發過程結束後,可以執行質量控制,以確保實現所需的配置。這一過程涉及通過光學或X射線顯微鏡檢查薄膜圖樣,以及二次測試來測量開發過程的準確性和完整性。總之,DMC SA/4m光刻工具是用於制造電路板和其他電子產品的先進資產。它能夠準確地曝光和開發光刻膠薄膜,為制造優質產品提供了必要的設計精度。該模型由柔性基層、感光聚合物層和涉及各種預處理和工藝包括光照、顯影和化學蝕刻的光刻工藝組成。質量控制過程用於驗證圖案膜在整個過程中是否符合規格。

還沒有評論