二手 TEL / TOKYO ELECTRON ACT 12 #9313699 待售

網址複製成功!

單擊可縮放

ID: 9313699

晶圓大小: 12"

優質的: 2004

System, 12"

Wafer type: Notch

Right to left

Loading configuration: (4) Loaders

Cassette type: FOUP

Main controller missing

Main system:

Mainframe with system controller

(4) Cassettes

(25) Slots

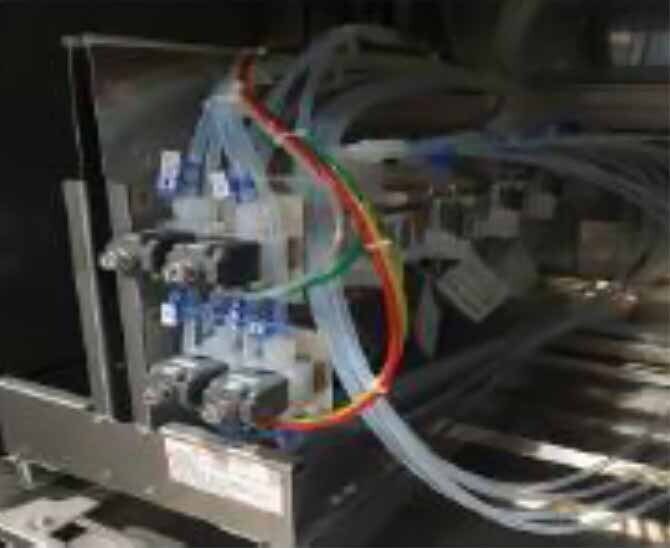

Coater unit (2-1, 2-2 Modules):

(4) Dispense nozzles with temperature controlled lines

RDS Pump

PR Suck-back valve: (8) Auto suck-back valves

Rinse nozzle: Back / EBR / Solvent bath for etch unit

Rinse system: 3-Liters (2) buffer tank systems

Thinner supply: CCSS

Programmable side rinse:

(4) PR Nozzles

(8) Bottles: (2) Bottles / (2) Nozzles

BCT Unit (2-3,2-4 Modules):

(4) Dispense nozzles with temperature controlled line

RDS Pump

PR Suck-back valve: (8) Auto suck-back valves

Rinse nozzle: Back / EBR / Solvent bath for each unit

Rinse system: 3-Liters (2) buffer tank systems

Thinner supply: CCSS Canister tank

Developer unit (3-1, 3-2, 3-3, 3-4 Modules):

NLD Nozzle / Unit

(2) System nozzles for DI rinse

2-Points for back side rinse

Developer system: 3-Liter (2) buffer tank systems

Developer supply: CCSS

Developer temperature control system

ASML I/F Wafer stage

(2) Adhesion units (ADH):

Sealing closed chamber with Built-in hot plate

HMDS Tank with float sensor

HMDS Supply: Local bottle

(4) Low temperature Hot Plates (LHP)

(3) High temperature Hot Plates (HHP)

(9) Chill plates (TCP)

(12) Precision Hot Plates (PHP)

(2) TRS Units

(2) Wafer Edge Exposure (WEE) Units

(2) Temperature Control Units (TCU)

OEM Type

Temperature control units (TCU) MFC controller

Chemical cabinets:

Cabinet 1: HNDS And solvent cabinet

Cabinet 2: DEV Solution chemical cabinet

Missing parts:

Main controller

T and H Controller

AC Power supply: 200/220 VAC, 668 A (Full-load Ampere)

2004 vintage.

TEL/TOKYO ELECTRON ACT 12是一款由TEL設計的光阻處理設備。它用於微加工和半導體器件制造過程。系統使用光刻工藝將所需的特征繪制到晶片上,然後蝕刻成金屬層。這一過程涉及將對紫外線敏感的光刻膠層暴露在圖樣上。暴露在光線下的區域變得堅硬,而剩下的區域則保持可溶性。硬區域充當蝕刻掩模,晶片使用光刻層形成的圖樣進行蝕刻。TEL ACT 12提供了準確且可重復的模式形成過程。高分辨率0.25微米,場大小5mm。該單元還可以在單程中執行雙級曝光循環,從而允許形成復雜的模式。該機器的設計考慮了模塊化和靈活性,並提供了一系列可選功能,可添加到工具中以增強其功能。此外,TOKYO ELECTRON ACT12的曝光時間很快,每晶圓的曝光時間只有2秒。這使得晶片的高吞吐量可以在短時間內得到處理。TOKYO ELECTRON ACT 12也使用線性掃描技術,確保在底物上有均勻劑量的紫外線。這樣可以形成更平滑、更精確定義的特征。此外,資產有一臺板載計算機,其中包含所有相關的風險參數,可以根據用戶的需要進行定制。總體而言,ACT 12是一個可靠和高效的工具,用於微加工和半導體器件制造過程。其高分辨率、快速曝光時間、高吞吐量、靈活的模型設計以及UV線性掃描,使其成為業內專業人士的理想選擇。

還沒有評論