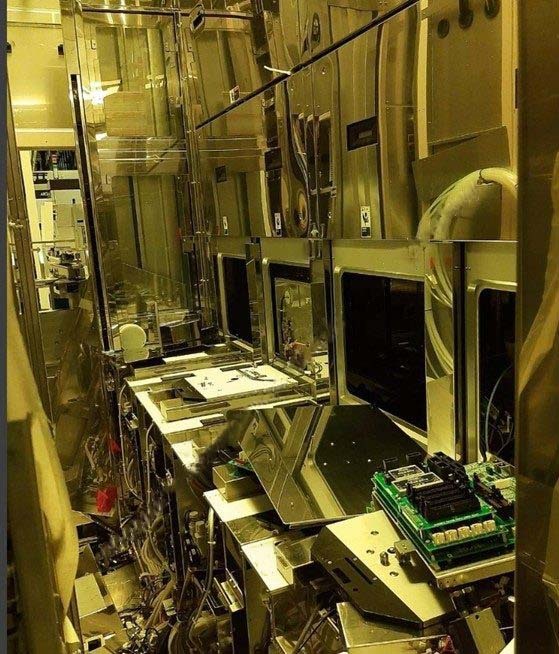

二手 TEL / TOKYO ELECTRON Clean Track ACT 12 #293604842 待售

看起來這件物品已經賣了。檢查下面的類似產品或與我們聯系,我們經驗豐富的團隊將為您找到它。

單擊可縮放

已售出

ID: 293604842

晶圓大小: 12"

優質的: 2008

Coater / Developer system, 12"

AC Power box

AC Power cable: 3 Phase

SHINWA T & H

Chemical cabinet: COT + DEV

(4) Coater units

(4) Develop units

(12) LHP Units

(2) HHP Units

(9) PHP Units

(9) CPL Units

(3) ADH Units

WEE Unit

(5) PEB Units

IRA Block

CSB

TCU

Coater unit:

Unit 1:

HPT Resist pump

EBR / RRC / BSR: EBR + RRC + Back rinse

Temperature / Humidity sensor

Photo resist temperature controller

Motor flange temperature controller

Unit 2:

(5) Resist nozzles

Resist pump: HPT

EBR / RRC / BSR: EBR + RRC + Back rinse

Temp / Humidity sensor

PR Auto exchange system

Photo resist temperature controller

Motor flange temperature controller

FOC Center photo resist drain

Unit 3:

(5) Resist nozzles

Resist pump: HPT

EBR / RRC / BSR: EBR + RRC + Back rinse

Temp / Humidity sensor

PR Auto exchange system

Photo resist temperature controller

Motor flange temperature controller

FOC Center photo resist drain

Unit 4:

(5) Resist nozzles

HPT Resist pump

EBR / RRC / BSR: EBR + RRC + Back rinse

Temperature / Humidity sensor

PR Auto exchange system

Photo resist temperature controller

Motor flange temperature controller

FOC center photo resist drain

Develop unit:

Unit 1:

Spray H develop nozzle

Rinse left to right develop nozzle move

Developer temperature control

Auto damper

Auto dummy rinse

Cup type: STD DEV

Unit 2:

Spray H nozzle develop nozzle

Left to right develop nozzle

(2) Top rinses

Developer temperature control

Auto damper

Cup type: STD DEV

Unit 3:

Spray H nozzle develop nozzle

Left to right develop nozzle

(2) Top rinses

Developer temperature control

Auto damper

Auto dummy rinse

Cup type: STD DEV

Unit 4:

Spray H develop nozzle type

Left to right develop nozzle move type

(2) Top rinses

Developer temperature control

Auto damper

Auto dummy rainse

Cup type: STD DEV

Hard Disk Drive (HDD) not included

2008 vintage.

TEL/TOKYO ELECTRON Clean Track ACT 12是利用超高壓清潔技術的光刻剝離設備。該系統能夠去除光致抗蝕劑,而不會損壞基板,也不會產生微粒。Clean Track單元由於其超高壓清潔技術,能夠以最小的損壞從基板上去除光刻膠。這樣可以確保基板不會因清潔過程而受損。除了超高壓清潔技術外,機器還利用多種清潔機制從基板上清洗光刻膠。其中包括強大的CO2激光器、用於化學去除的霧化器、用於去除顆粒的晶圓清潔器以及用於機械作用的攪拌站。CO2激光器能夠有選擇地切除和去除基板上的光致抗蝕劑,而不會對底層造成損害。霧化器用於在基材上添加適當的化學溶液,溶解光刻膠並確保其被完全去除。晶圓清潔器設計用於清除清潔過程中基板上殘留的任何顆粒。最後,攪拌站允許機械作用,進一步方便清洗過程。Clean Track工具還設計為提供自動化,從而實現高效和一致的結果。集成的控制資產和自動晶片處理可確保快速、準確地執行清潔過程。此外,真空泵技術還提供了較高的空氣去除能力和快速幹燥時間,確保從基板表面完全去除光致抗蝕劑。TEL Clean Track ACT 12模型是一種可靠高效的光敏剝離設備。它結合超高壓清潔技術和其他清潔機制,為從基板上去除光刻膠提供了一個幹凈、準確、一致的系統。通過提供自動化、一致的結果,Clean Track單元可以幫助提高光刻工藝的效率,並使制造商能夠生產更高質量的基板。

還沒有評論