二手 TEL / TOKYO ELECTRON Clean Track ACT 12 #9282380 待售

網址複製成功!

單擊可縮放

ID: 9282380

晶圓大小: 12"

優質的: 2003

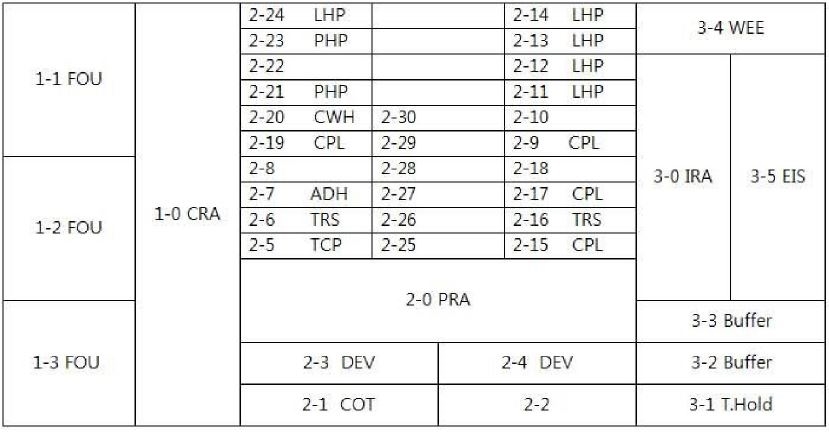

Coater / Developer system, 12"

Left to Right

FOUP carrier

(3) FOUP Loader uni-cassetes

(3) Main controllers

(2) Thermo controllers

(2) Fire system boxes

PRB

CSB

IFB

Main system:

Main frame with system controller

Carrier station

FOUP Cassette

(3) Cassettes

Uni-cassette system

Coater unit:

(6) Dispense nozzles

With temperature control line

MILLIPORE RDS Pump

Rinse nozzle: EBR / Back rinse / Solvent bath

Rinse system: (2) Buffer tank systems (3-Liters)

Degassing system

Programmable side rinse

PR Nozzle

(6) Bottles

Thinner supply: CCSS

AMC Suck-back valve

Direct drain

Developer unit:

H Nozzle:

Stream nozzles for DI rinse

2-Points for back side rinse

Developer systems: (2) Buffer tank systems (3 Liters)

Developer supply: CCSS

Degassing system

Developer temperature control system

Direct drain

NIKON SF130 Wafer stage

Adhesion units:

100% Sealing closed chamber (Built-in hot plate)

HMDS Tank with float sensor

HMDS Supply

(5) Low temperature Hot Plates (LHP)

(4) Chill Plates (CPL)

(2) Precision chilling Hot Plates (PHP)

TCP Unit

(2) TRS Units

Wafer Edge Exposure (WEE) unit

I-line UV Sensor

Chemical cabinet 1: HNDS and Solvent supply system

Chemical cabinet 2: DEV Solution and DIW supply system

SHINWA Series ESA-8 Humidity controller

Temperature Control Units (TCU)

AC Power box

2003 vintage.

TEL/TOKYO ELECTRON CLEan Track ACT 12是一種光刻膠(PR)設備,旨在使半導體器件的生產速度更快、效率更高。它是一種高度先進的解決方案,用於創建在矽片表面上傳輸電信號的復雜模式。該系統由幾個不同的組成部分組成,其中一些設計是為了優化模式的準確性並保證很高的產量。第一個是TEL clean track ETCH單元。這臺機器采用幹蝕刻和化學蝕刻的組合,以確保晶圓是正確的圖案。還有一個先進的光刻工具,用於精確設置公關資產。該模型還包括用於控制PR層速度和優化電子數據傳輸的交流磁鐵設備。該系統還旨在減少或消除生產過程中的任何缺陷。TEL Clean Track ACT 12非常可靠,有幾個內置的安全系統。其中之一是Clean-Track流程監控單元。這臺機器確保每個過程步驟都受到監視,並且任何錯誤都可以得到糾正。該工具還具有用於實時表面監視的串聯鏡像資產,以確保正確應用PR層。TOKYO ELECTRON Clean Track ACT 12的另一個重要特點是它能夠根據正在生產的產品的需要快速改變PR層的參數。這樣可以提供高度的靈活性和更快的生產時間。最後,該模型還能夠自動檢測生產過程中的任何缺陷。這樣可以實現更全面、更快速的質量控制,並能夠快速解決任何錯誤。總體而言,Clean Track ACT 12是一種高度先進和高效的光敏設備。它兼具創新特性和可靠性,是快速準確生產半導體器件的理想選擇。

還沒有評論