二手 TEL / TOKYO ELECTRON Clean Track ACT 8 #9182601 待售

看起來這件物品已經賣了。檢查下面的類似產品或與我們聯系,我們經驗豐富的團隊將為您找到它。

單擊可縮放

已售出

ID: 9182601

晶圓大小: 8"

優質的: 2004

(3) Coaters / (3) Developers, 8"

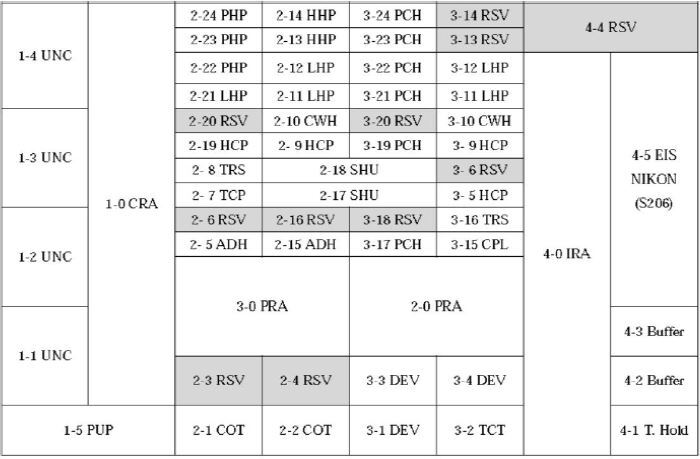

General system configuration:

Left to right

Carrier type: Notch type, (25) Slots

System power rating: AC 208V, 3-Phase for system, 173A (Max)

Loading configuration:

(4) Loaders

Uni-cassette

Software version: 3.04.130

(3) Main controllers

Main system details:

Main frame with system controller

Carrier station

Type: Normal cassette type

Cassette: (25) Slots

Coater unit details (2-1, 2-2 module):

(8) Dispense nozzles

with temperature controlled lines for etch unit

(16) RRC Pumps

PR Suck-back valve: (16) AMC Suck-back valves

Rinse nozzle: Back / EBR / Solvent bath for etch unit

Rinse system: 3-Liter 2-tank buffer tank system

Programmable side rinse

PR Supply (1, 2, 3, 4, 5, 6, 7, 8): (8)Bottles (1-Bottle / 2-Nozzle)

Solvent Supply

CCSS Supply

E.B.R Flow system: CCD Type

Drain type: Direct drain system (Including a pump)

TCT Unit details (3-2 Module):

(3) Dispense nozzles with temperature controlled

Resist 1, 2 RRC pump (F-T201-1)

Resist 3 RDS pump (R GEN tm-01)

PR Suck-back valve: (3) AMC Suck-back valves

Rinse nozzle: Back / EBR / Solvent bath for etch unit

Rinse system: 3-Liter 2-tank buffer tank system

Programmable side rinse

PR Supply (1, 2, 3): (3) Bottles (1-Bottle/1-Nozzle)

Solvent supply: CCSS Supply

E.B.R Flow system: CCD Type

Drain type: Direct drain system (Including a pump)

Developer unit details (3-1, 3-2, 3-4 Module):

(1) LD Nozzle for each unit

(3) Dispense nozzles with temperature controlled

(1) Stream nozzle for DI rinse

2-Point for back side rinse on each unit

Developer system: (3) 3-Liter 2-tank buffer tank system

Developer supply: CCSS Supply

Developer temperature control system

Drain: Direct drain

I/F Wafer stage type: NIKON Type (S206)

(2) Adhesion units details:

HMDS Tank with float sensor in system

HMDS Supply: Local canister supply

(3) Precision hot plate stations (PHP)

(6) Precision chilling hot plate stations (PCH)

(2) Cup washer holders (CWH)

(4) High chill plate stations (HCP)

(1) Chill plate station (CPL)

(2) High temp hot plate stations (HHP)

(5) Low temp hot plate stations (LHP)

(2) Transition stages (TRS)

(1) Transition chill plate (TCP)

Chemical cabinet #1: PR Bottle & 2-1, 2-2 COT pump

HMDS Buffer tank assembly

Solvent buffer tank

Solvent filter assembly

Developer buffer tank & developer / DI filter assembly

Chemical cabinet #2: HMDS Canister tank

Temperature & humidity controller:

Type: SHINWA ESA-8Series (TEL OEM)

Temperature control unit (TCU):

Type: TEL OEM

AC Power box:

AC 200/220V

Full load current: 173A

System configuration:

(1) UNC: Uni-cassette stage

(1) TCT: TARC Process station

(2) ADH: Adhesion process stations

(3) PHP: Precision hot plate stations

(6) PCH: Precision chilling hot plate stations

(2) CWH: Cup washer holders

(2) SHU: Shuttles

(2) COT: Coat process stations

(3) DEV: Develop process stations

(4) HCP: High speed chill plate stations

(1)CPL: Chill plate station

(2) HHP: High temperature hot plate stations

(5) LHP: Low temperature hot plate stations

(2) TRS: Transition stages

(1) TCP: Transition chill plate

Other system details:

In-Line

CSB, PRB1, PRB2, IFB

Power box, T&H Controller 1

Chemical box 1, 2

Thermo-controller 1

2004 vintage.

TEL/TOKYO ELECTRON CLEan Track ACT 8是專門為液晶面板生產線設計的光刻設備。光致抗蝕劑系統使用紫外線(UV)來暴露塗在基板表面的光致抗蝕劑材料,通常是玻璃。如果基板暴露在適當波長的光下,抗蝕劑會分解,留下暴露和未暴露區域的圖案。LCD面板生產線采用這種光刻技術,在LCD面板上制作出超細的電極圖案。TEL Clean Track ACT 8為液晶生產線提供了可靠的模式形成。它是一個模塊化系統,由一個曝光單元、一個焦點和對準單元、一個基板級模塊、一個測量和控制單元以及一個支撐控制機器組成。曝光單元利用強大的UV-LED光源以及各種光學器件和檢流計,通過高度精確的對準和像差控制提供卓越的曝光穩定性。聚焦和對準工具允許精確和可重復的圖樣定位,允許精確和精確的電極圖樣形成。基板級模塊提供精確的運動速度和精度,使得極精確的圖案形成。測量和控制單元自動調整和控制每個曝光單元的曝光水平。支持控制資產同步硬件組件,並提供用戶友好界面,允許用戶監控、調整和分析生產線上每個曝光單元的曝光水平。TOKYO ELECTRON CLEAN Track ACT 8旨在最大限度地提高生產力,同時提供卓越的抗拒定義和模式精度。它提供了最小線寬為0.1微米、均勻度為± 2%的高分辨率圖案。它還提供快速曝光時間,以滿足液晶生產線的高需求。Clean Track ACT 8以其卓越的曝光均勻性和高精度,是液晶面板生產線的絕佳選擇。

還沒有評論