二手 TEL / TOKYO ELECTRON Clean Track Mark 8 #9158015 待售

網址複製成功!

單擊可縮放

ID: 9158015

晶圓大小: 8"

優質的: 1997

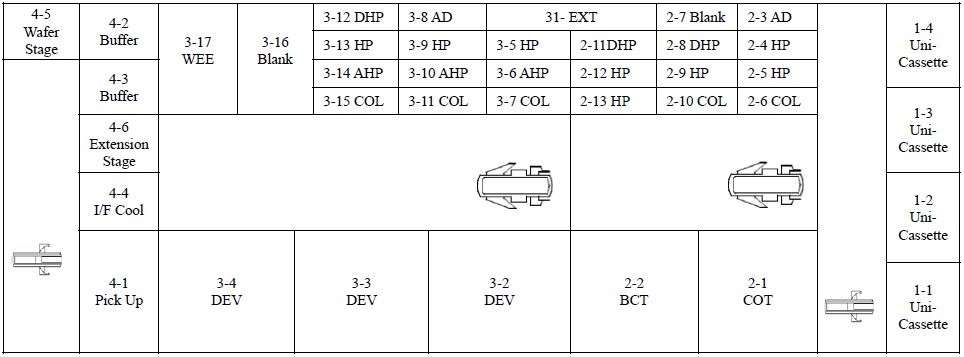

(2) Coater / (3) Developer system, 8"

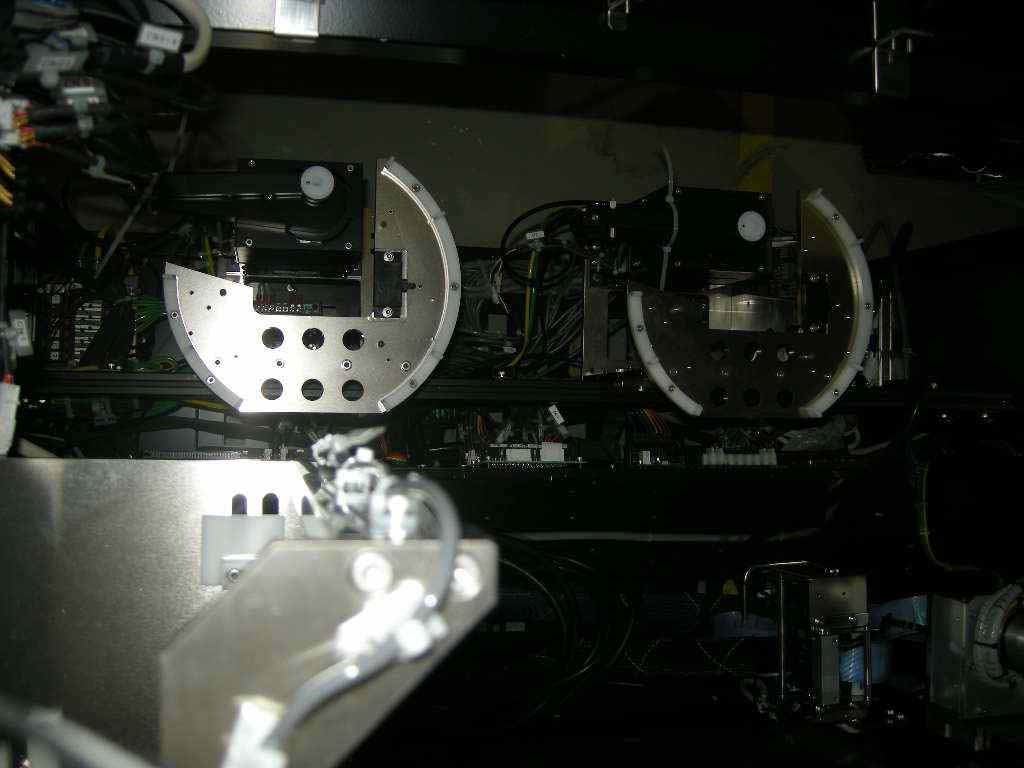

Dual block

Silicon substrate wafer

Wafer flow: Right to left

CSB Unit at right

Interface station unit at left

(2) Process blocks:

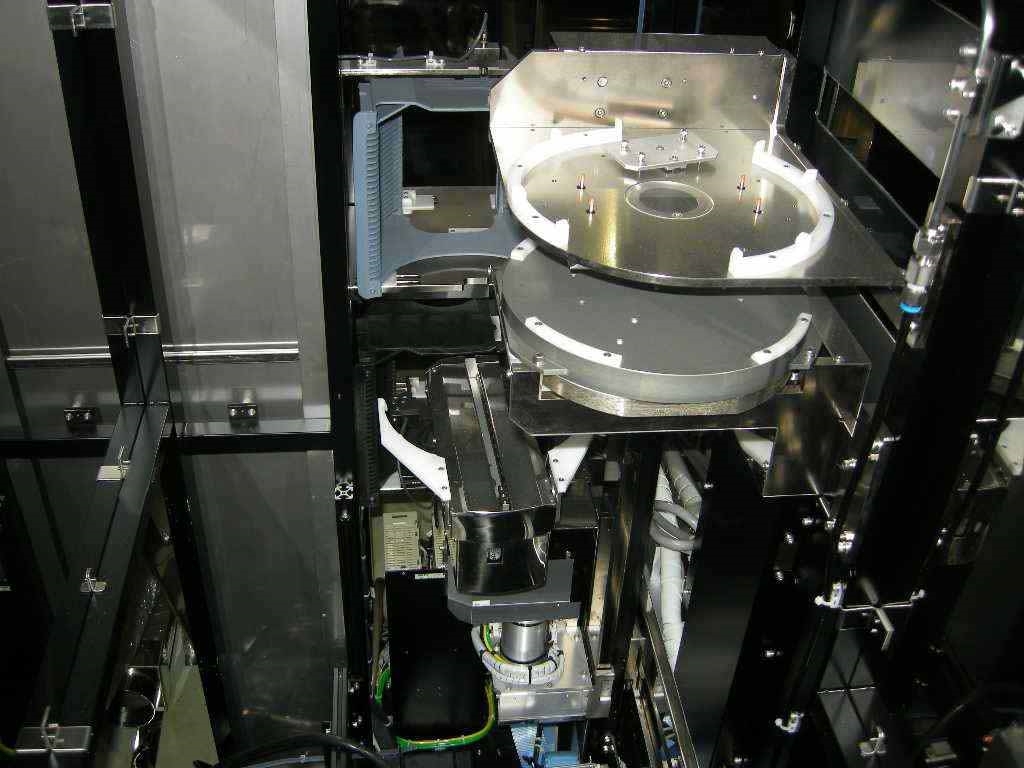

Cassette station block (CSB):

FC-9801F Controller

Stage / Indexer:

Non SMIF / Open uni-cassette

Cassette station (CS)

Cassette station arm (CSA)

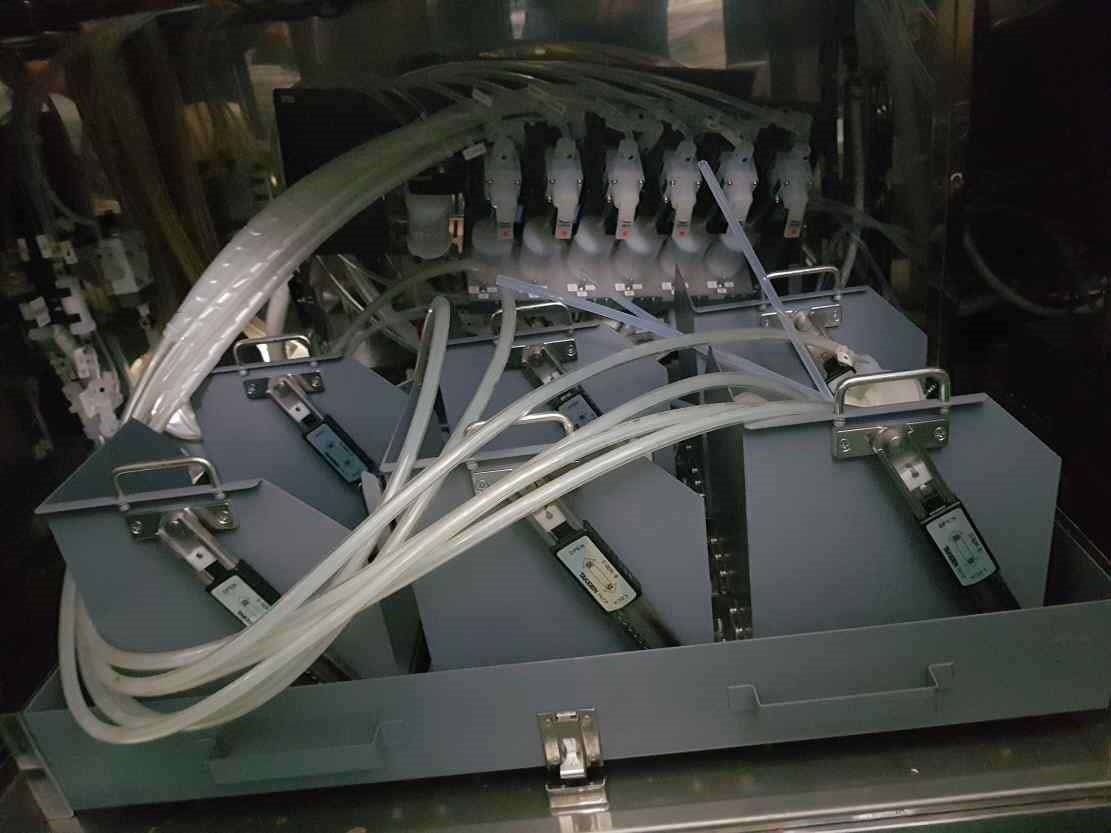

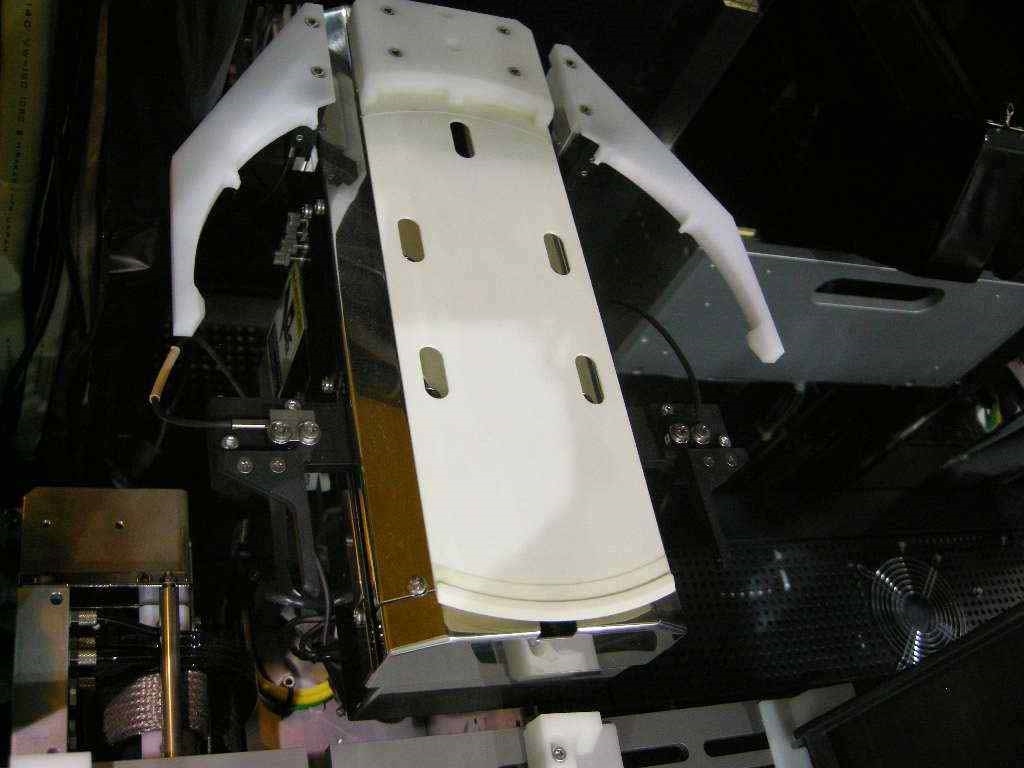

PSB / Process station block (Spin units):

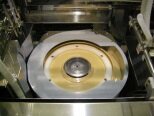

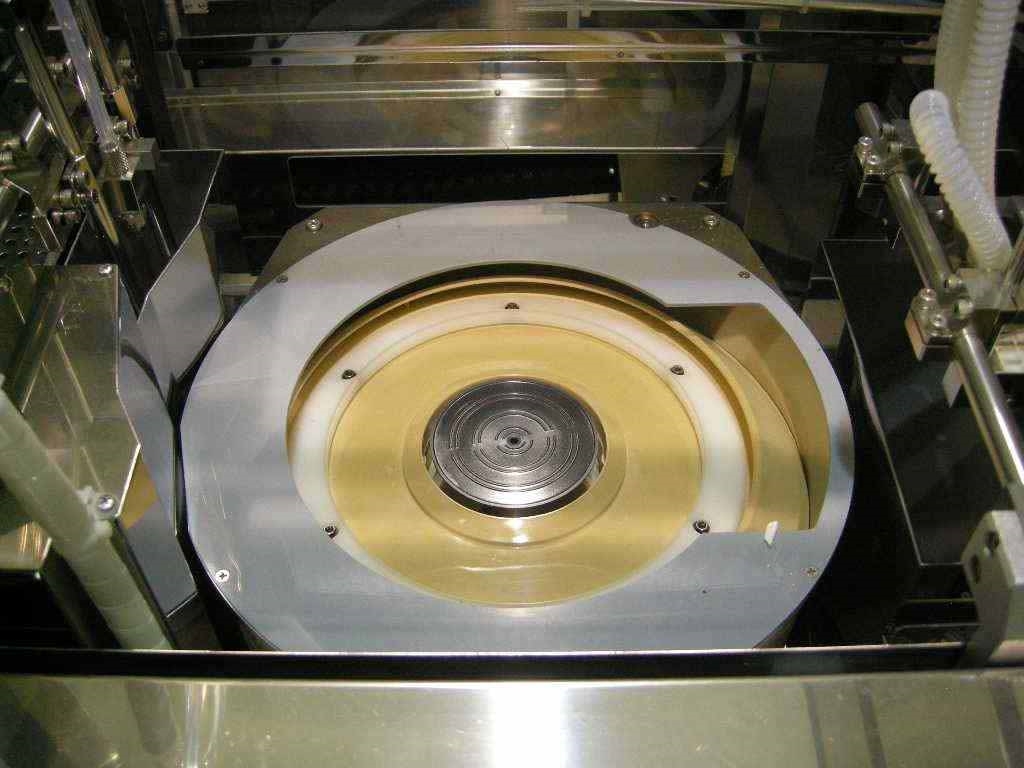

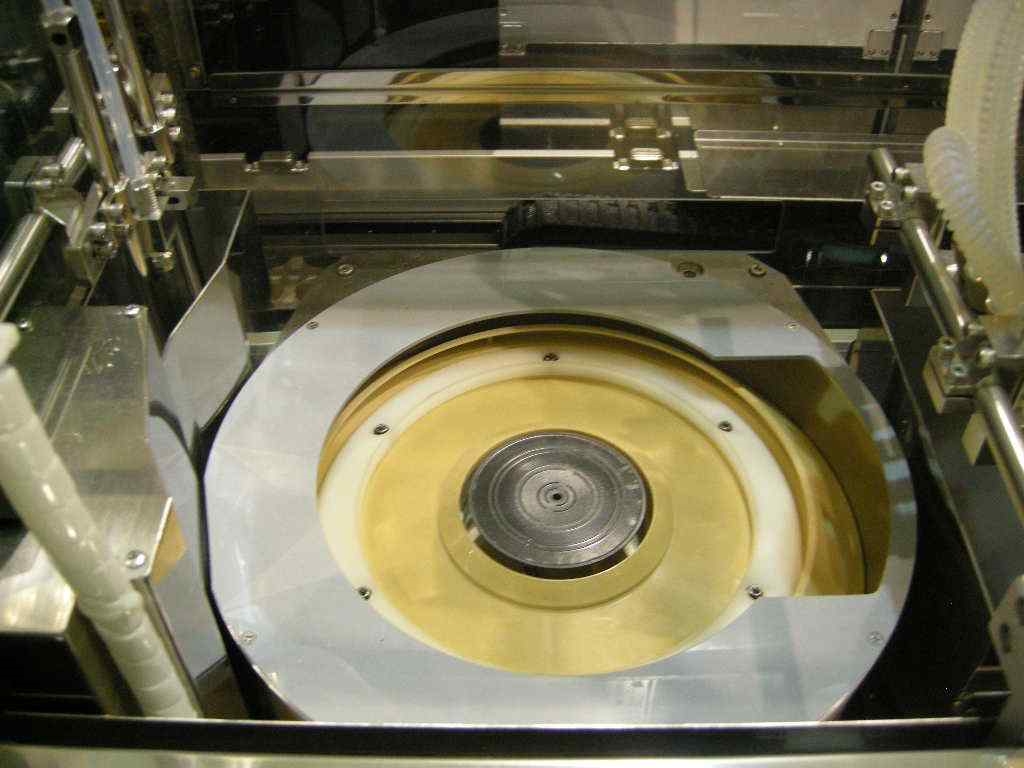

2-1 Standard photo resist coat unit:

(3) Photo resist dispense nozzles

(3) IWAKI Bellows pumps

Solvent pre-wet reduced resist coat (RRC) nozzle

Side rinse nozzle (Programmable side rinse EBR)

Dual back rinse nozzles

Photo resist temperature control

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

(6) Photo resist bottles in external chemical supply systems

Photo resist auto exchange

Auto dummy dispense system

2-2 Bottom layer coat (BCT) unit:

(3) Bottom layer coat (BCT) dispense nozzles

(3) IWAKI Bellows photo resist pumps

Solvent pre-wet reduced resist coat (RRC) nozzle

Side rinse nozzle (Programmable side rinse EBR)

Dual back rinse nozzle

Photo resist temperature control

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

Photo resist bottle: (6) External photo resist supply system

Photo resist auto exchange

Auto dummy dispense system

Process block robotics arm (PRA)

Adhesion unit (AD)

(5) Hot plate oven units

(2) Dehydration hot plate (DHP) oven units

(2) Cool plate units

Process station block (Spin units):

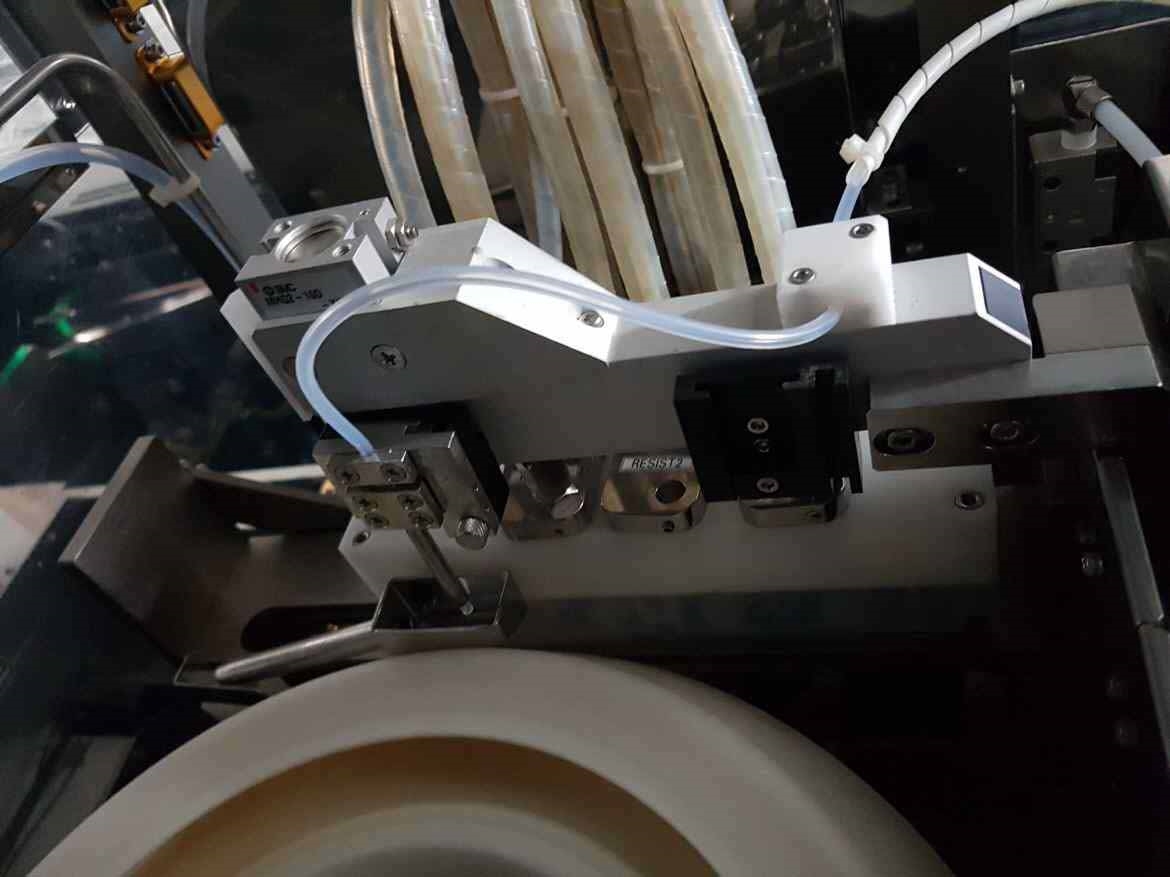

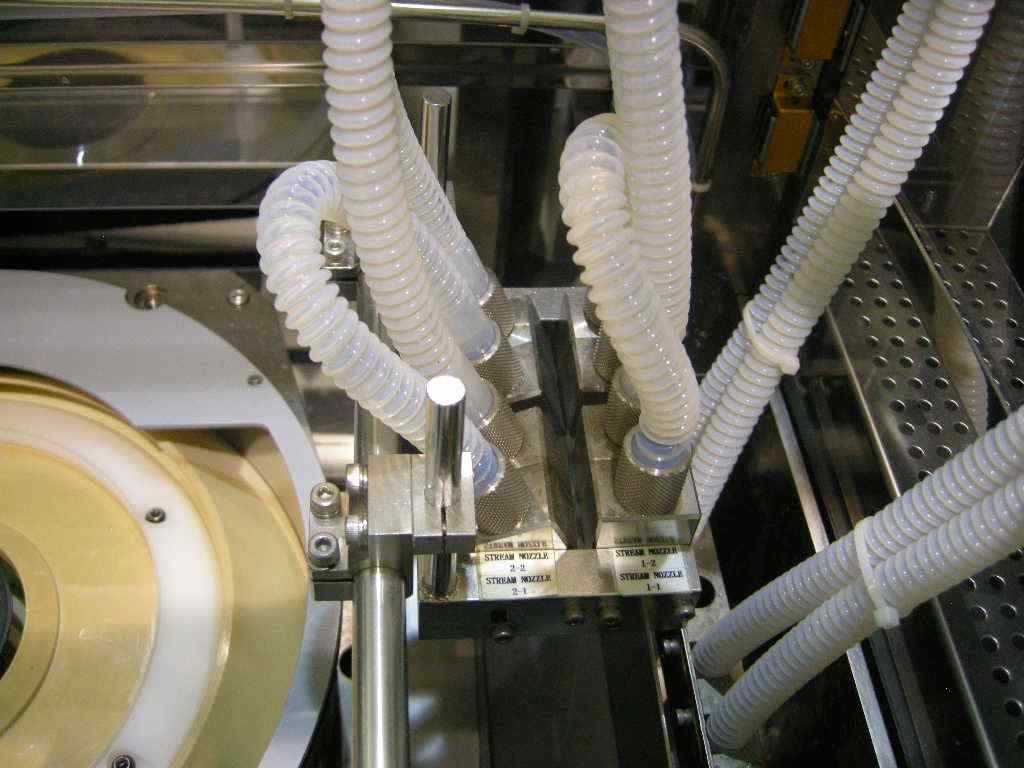

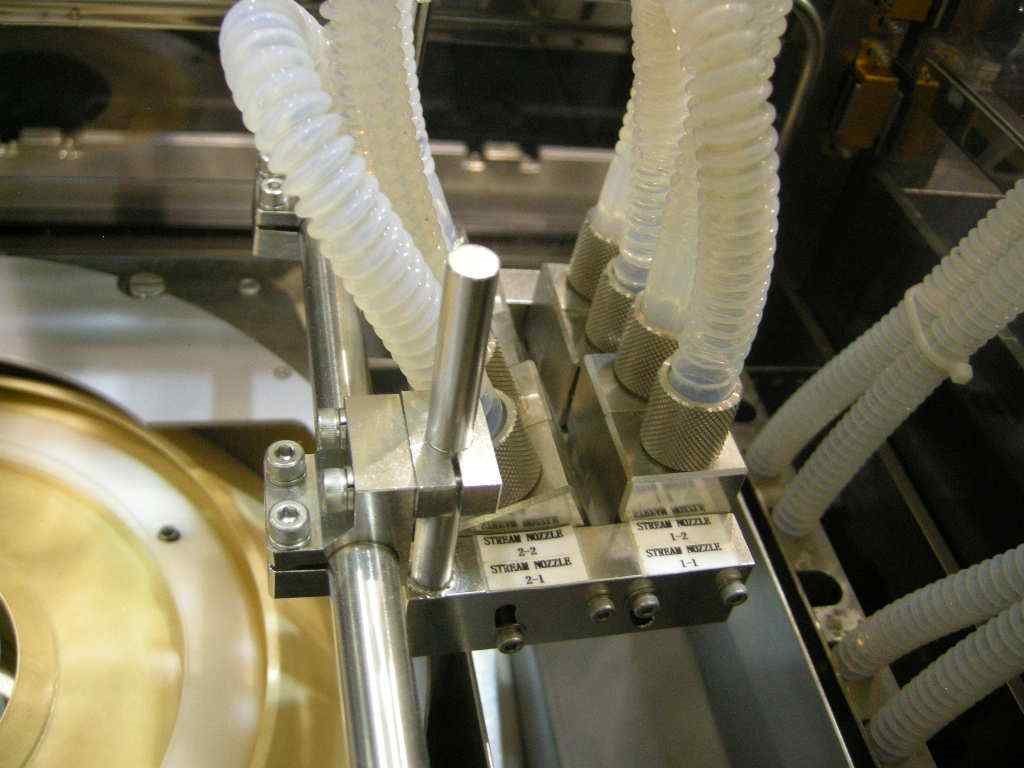

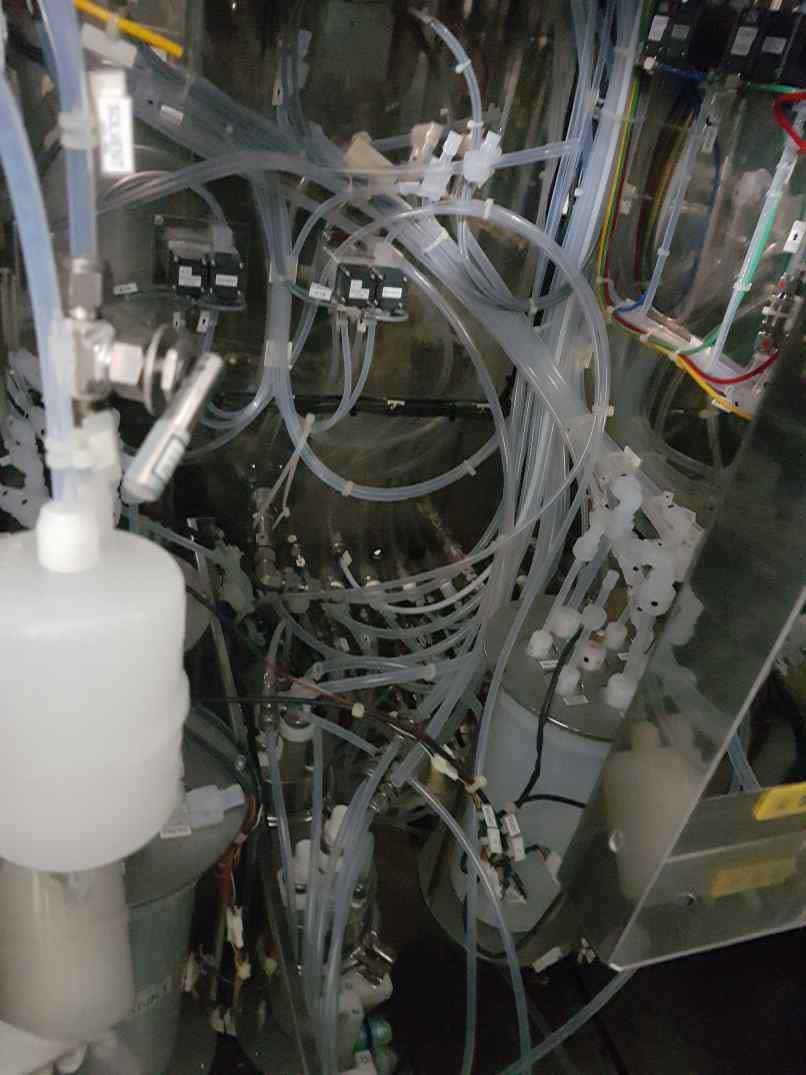

3-2, 3-3, 3-4 Develop units:

(4) Stream nozzles at (4) Stream nozzle blocks

Rinse nozzles:

(2) Stream type

Spray type

Dual back rinse nozzles

Develop temperature control

Motor flange temperature control

Drain type: Direct gravity drain type

Auto damper

Auto dummy dispense system

Process block robotics (PRA) Arm

Adhesion unit

(3) Hot plate oven units

Dehydration hot plate (DHP) oven unit

(3) Air-purge hot plate (AHP) oven units

(3) Cool plate units

Extension unit

Wafer edge exposure (WEE) unit

Interface station block (IFB):

Interface arm (IFA)

Interface for ASML PAS Series Stepper

(2) Buffers

Pick-up system

Interface cool

Extension stage

Wafer stage

Temperature and humidity controller:

TEAM KOREA TK-TH8T4

2-Cup control capacity for 2 Coat units

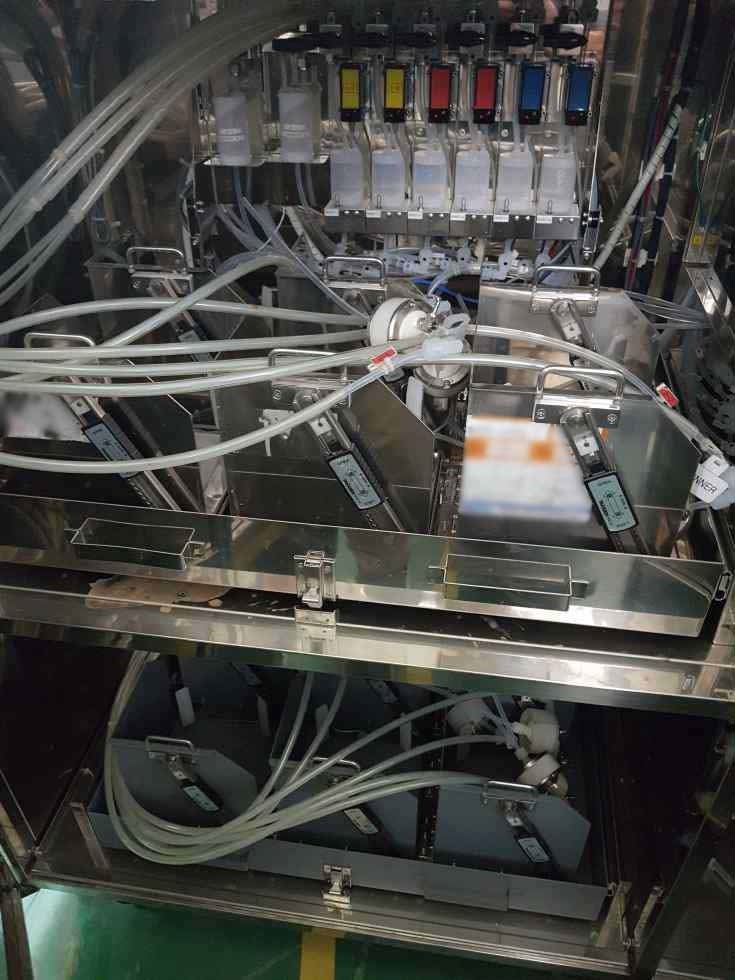

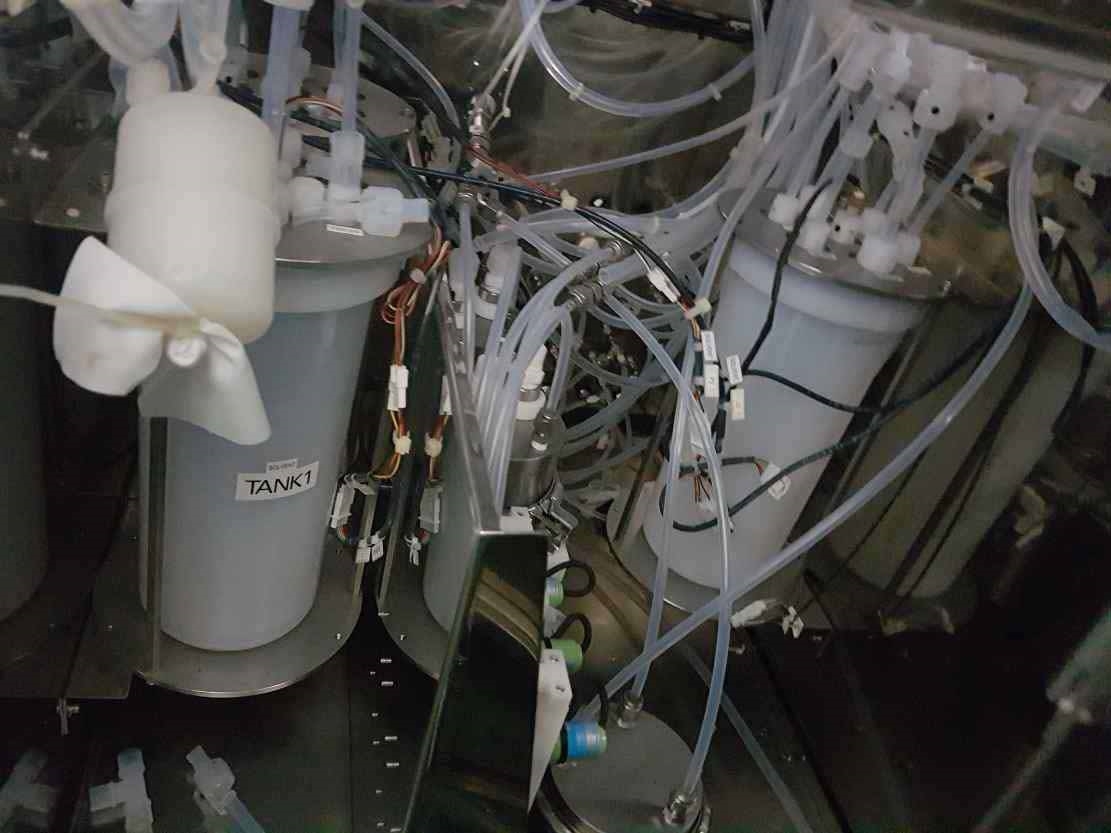

External chemical supply system:

Solvent supply system:

Solvent chemical type

CSS Bulk-fill to auto supply system

With (2) Buffer tanks: Auto switch-off / Exchange

Develop supply system:

Develop solution chemical type

CSS Bulk-fill to auto supply system

With (2) Buffer tanks: Auto switch-off / Exchange

Photo resist supply system for 2-1 Coat and 2-2 BCT

6-Bottles of manual supply type

Auto exchange system

HMDS Supply system:

HMDS Chemical type

CSS Bulk-fill to auto supply system with bubbling jar

HMDS Supply system

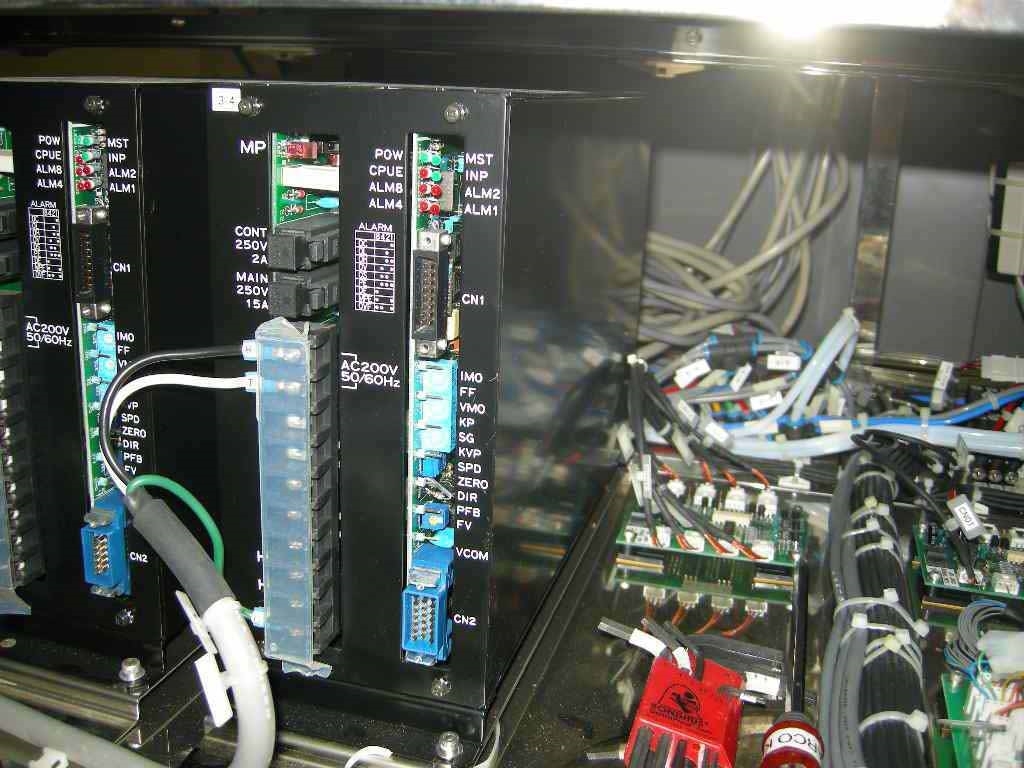

Themo controller:

External chemical supply system: (2) TEL / TOKYO ELECTRON SMC Multi controller

MAX 16 Channel capacity: 12-Channels for (2) Process

SMC Multi thermo controllers:

(6) SMC Circulators: Chilling channels

2-1 COT Unit

2-2 BCT Unit

Stream nozzle block:

Block 1 and 3: 3-2, 3-3 DEV

Block 2 and 4: 3-4 DEV

(5) Motor flanges

(6) SMC Thermo controllers: Chilling channels

2-9 COL

2-10 COL

3-7 COL

3-11 COL

3-15 COL

4-4 I/F COL

(4) Robots:

CS Arm

(2) Main arm robots

Interface arm

Power transformer AC cabinet: 208 VAC, 3-Phase, 50/60 Hz

1997 vintage.

TEL(TOKYO ELECTRON)TEL/TOKYO ELECTRON CLEan Track Mark 8是一款用於製造電路板的光敏設備。該系統能夠進行各種光刻過程,包括旋轉塗層、軟烘烤、面膜對準、噴塗和硬烘烤。幹凈的軌道可以實現可重復和準確的結果,從而幫助創造高產率。TEL Clean Track Mark 8旨在幫助減少清潔空間停機時間並提高工作效率。它具有耐用、可靠的防靜電底盤和「no-ccd」對齊單元,可將對齊時間縮短一半。此外,該機還配備了觸摸面板液晶顯示屏,這使得導航工具的功能更加容易。該資產包括兩種獨特和先進的烘烤技術,以提高清潔度和工藝精度。首先是分裂烘烤,將烘烤過程分成兩部分,降低汙染風險,優化溫度穩定性。二是混合烘烤,可以完全烘烤晶圓,而不會將基材分離成任務。TOKYO ELECTRON Clean Track Mark 8採用特別設計的噴嘴和清潔劑,能夠快速清除抗拒殘留物,導致更清潔的晶片,同時大幅減少化學廢棄物的產生。特殊的塗層功能可將化學用量和清潔時間減少70%之多,陶瓷頭噴嘴有助於減少總顆粒數量,而高精度的無接觸跟蹤有助於提高對準精度。此外,該模型是可改造的,它允許與各種光刻膠系統兼容。總體而言,Clean Track Mark 8使用先進技術,使用戶能夠獲得可重復和一流的結果,同時最大限度地減少化學品、能源和停機時間的使用。它被設計成一種高效的光敏設備,幫助用戶在保持成本效益的生產的同時達到最大產量。

還沒有評論