二手 TEL / TOKYO ELECTRON Clean Track Mark 8 #9165442 待售

網址複製成功!

單擊可縮放

ID: 9165442

晶圓大小: 8"

優質的: 1997

(2) Coater / (2) Developer system, 8"

Single block

Open cassette

Interface for NIKON NSR 2205 EX14C

Silicon substrate wafer

Wafer flow: Left to right

CSB Unit at right

Interface station unit at left

(2) Process blocks: Single block system

Cassette station block (CSB):

FC-9821KE Controller

Stage / Indexer:

Non SMIF / Open uni-cassette

Cassette station (CS)

Cassette station arm (CSA)

Process station block (Spin units):

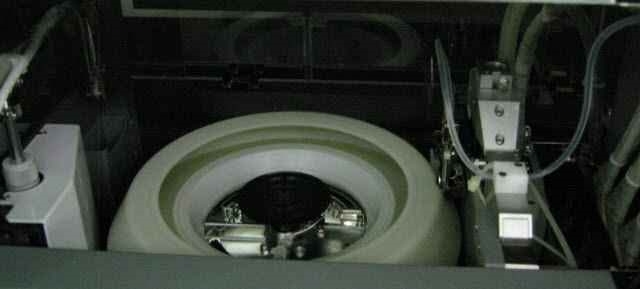

2-1 Standard photo resist coat unit:

(3) Photo resist dispense nozzles

(3) IWAKI Bellows pumps

Solvent pre-wet reduced resist coat (RRC) nozzle

Side rinse nozzle (Programmable side rinse EBR)

Dual back rinse nozzles

Photo resist temperature control

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

Auto dummy dispense system installed

Photo resist bottle: (6) External chemical supply system

2-2 Anti-reflection coat unit:

(3) Photo resist dispense nozzles

(3) IWAKI Bellows photo resist pumps

Solvent pre-wet reduced resist coat (RRC) nozzle

Side rinse nozzle (Programmable side rinse EBR)

Dual back rinse nozzles

Photo resist temperature control

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

Auto dummy dispense system installed

Photo resist bottle: (6) External chemical supply system

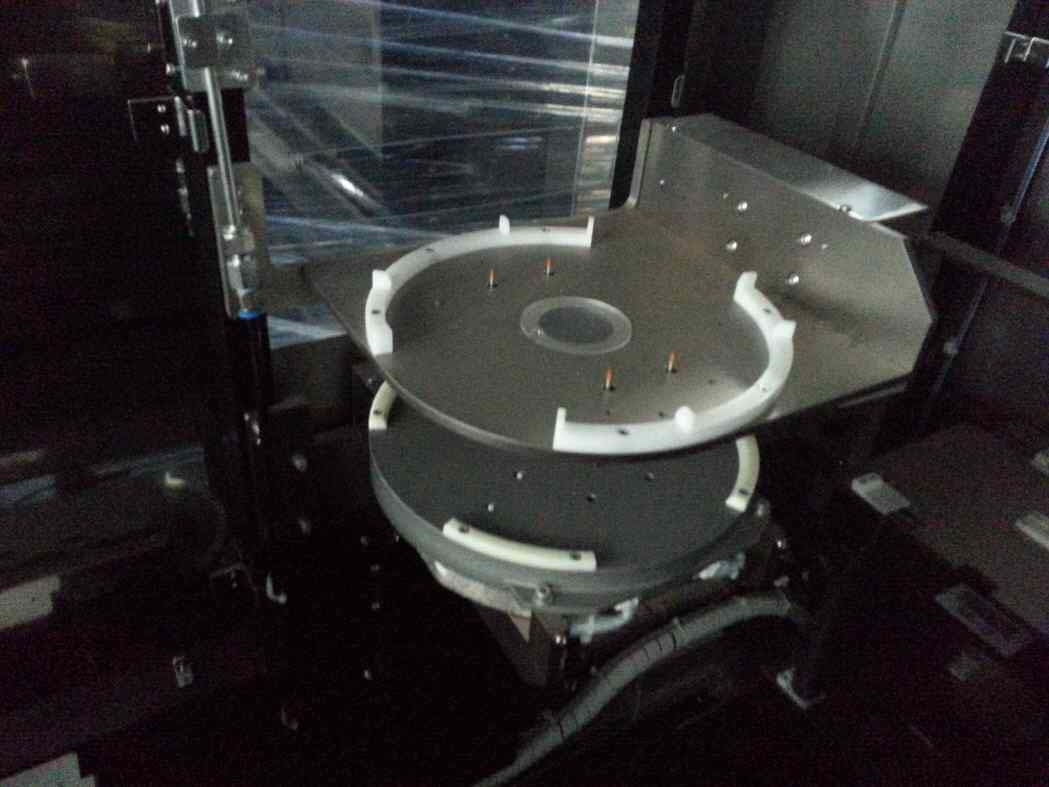

2-3 and 2-4 Develop units:

(4) Stream nozzle blocks

(4) Stream nozzles

(2) Rinse nozzles: Stream type

Dual back rinse nozzles

Develop temperature control

Motor flange temperature control

Drain type: Direct gravity drain type

Auto damper

Auto dummy dispense system

Process block robotics arm (PRA)

Adhesion unit

(10) Hot plate oven units

(2) Air-purge hot plate (AHP) oven units

(7) Cool plate units

Wafer edge exposure (WEE) unit

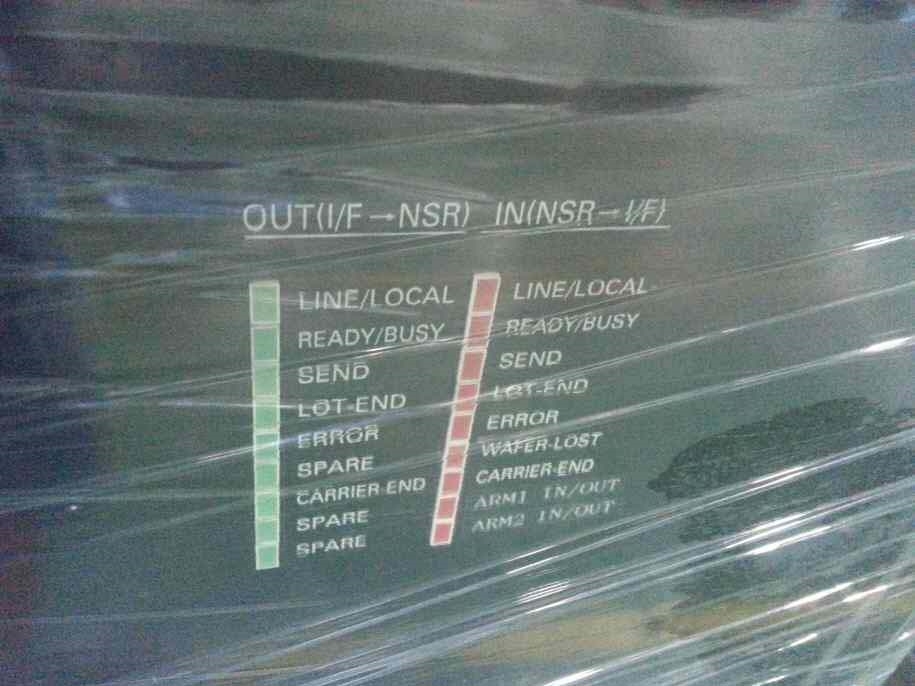

Interface station block (IFB):

Interface arm (IFA)

(2) Buffers

Pick-up system

Interface cool

Extension stage

Wafer stage

Temperature and humidity controller:

SHINWA T&H-CPC

2-Cup control capacity for (2) Coat units

External chemical supply system:

Solvent supply system for (2-1) COT and (2-2) ARC:

Solvent chemical type

Bulk-fill central chemical supply (CSS) type

With (2) 3-Liter teflon buffer tanks

Develop supply system for 2-3 and 2-4 Develop units:

Develop solution chemical type

Bulk-fill central chemical supply (CSS) type

With (2) 3-Liter teflon buffer tanks

(2) Photo resist supply systems:

6-Bottles of manual supply type

Auto switch-off / Exchange installed

HMDS Supply system:

HMDS Chemical type

Bulk-fill central chemical supply (CSS) type

With 3-Liter teflon buffer tanks for AD unit

External chemical supply system / Cabinet: (2) SMC Multi thermo controller units

SMC Circulator pumps and thermo controller

With 7-Channels:

2-1 COT

2-2 ARC

Motor flanges: 2-1 COT and 2-2 ARC

2-8 COL

2-12 COL

2-16 COL

2-19 COL

SMC Circulator pumps and thermo controller

With 7-Channels:

1 and 3 Stream nozzle blocks: 2-3

2 and 4 Stream nozzle blocks: 2-4

(2) Motor flanges at 2-3 and 2-4 DEV

2-20 COL

2-23 COL

2-24 COL

3-4 I/F COL

(3) Robots:

CS Arm

Main arm robots

Interface arm

Power transformer AC cabinet: 208 VAC, 3-Phase, 50/60 Hz

1997 vintage.

TEL/TOKYO ELECTRON CLEAN Track Mark 8是為滿足當今超高可靠性和高精度電路板的要求而開發的光刻膠系統。Mark 8采用了先進的超聲波接觸清潔(UCC)方法,配備了兩步式的「吹氣清洗和掃描清洗」工藝。Airblow Cleaning process uses a high-speed air flow to remove dust, dust, and contains up at a some size.它利用強制氣流清潔表面,而不會對基板造成任何損害或應力。「掃描清潔」過程采用了使用旋轉刷子的往復式清潔方法。這將清除空氣吹掃過程後殘留的小汙染物。Mark 8還包含一些其他功能,以提高性能和輸出。其中包括使用特定密度清潔器(SDC)、CCD相機進行缺陷檢測、板室溫度控制、硬件和軟件警報監控、Shimura/Kitta缺陷檢測、自動化學水平控制和卷帶式芯片粘度控制。Mark 8還具有額外的靈活性和可定制的板基級,使其能夠處理高應變和低應變傳感器基板,以及標準化和非標準化基板。此外,該工具還集成了高度感應傳感器,從而減少了在加工過程中出現顆粒汙染的機會,並提高了性能。在當今高精度電路板時代,TEL Clean Track Mark 8光刻系統滿足了客戶的性能和可靠性需求。它具有先進的UCC功能和幾個附加功能,有助於為客戶提供一貫清潔、高質量的基板。憑借Mark 8的多功能性和高級功能,它能夠滿足最苛刻的要求,確保無與倫比的性能。

還沒有評論